Ball nose Tungsten Carbide End Mill bakeng sa aluminium

Likaroloana

Likarolo tsa mill nose carbide end Mills tse etselitsoeng ka ho khetheha bakeng sa machining a aluminium li kenyelletsa:

1. E entsoe ka tungsten carbide e tiileng, e nang le boima bo phahameng le ho hanyetsa ho apara, e loketseng haholo bakeng sa ho itšeha aluminium le lisebelisoa tse ling tsa tšepe tse se nang ferrous.

2.Moqapi oa hlooho ea bolo o lumella li-contours tse boreleli le likarolo tsa likarolo tsa aluminium, tse hlahisang libaka tse pota-potileng hantle kapa tse betliloeng.

3. Hangata e koahetsoe ka seaparo se khethehileng, se kang TiAlN (Titanium Aluminium Nitride) kapa AlTiN (Titanium Aluminium Nitride), ho matlafatsa ho hanyetsa mocheso le ho fokotsa ho ferekana, ho ntlafatsa bophelo ba lisebelisoa le tshebetso.

4. Moralo oa ho tlosa li-groove le ts'ebetso ea ho tlosa chip e ntlafalitsoe bakeng sa ts'ebetso ea aluminium ho netefatsa ho tlosoa ha li-chips ka katleho le ho thibela ho bokellana ha chip nakong ea ho itšeha.

5. Ka lebaka la ho kopanya lisebelisoa tsa carbide le liaparo tse khethehileng, machining a lebelo le phahameng a khoneha, kahoo a ntlafatsa tlhahiso le ho qeta holimo.

6. Sebopeho se matla le geometry ea li-mill tsa ho qetela li fokotsa ho senyeha ha lisebelisoa, ho lumella ho sebetsa ka mokhoa o tsitsitseng le o nepahetseng oa likarolo tsa aluminium.

7. E khona ho hlahisa boleng ba boleng bo phahameng holim'a likarolo tsa aluminium, e leng se etsang hore e tšoanelehe bakeng sa likopo moo botle ba holimo bo leng bohlokoa.

8. E etselitsoe hore e lumellane le mechine ea CNC le litsi tsa ho sila, e fana ka mefuta e mengata ea lisebelisoa tse fapaneng tsa lisebelisoa tsa aluminium.

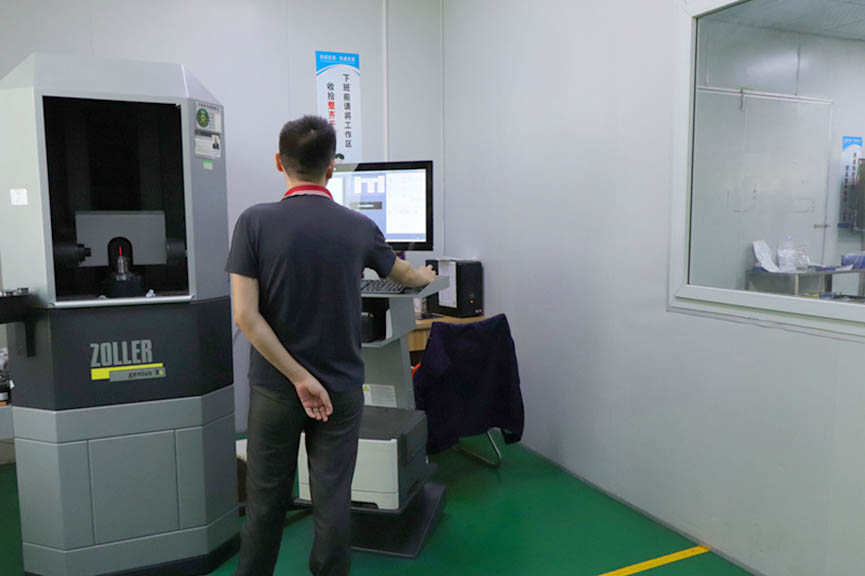

BONTŠA SEHLAHISO