Lisebelisoa tsa boleng bo holimo tsa HSS Flat End tse nang le 4 Flutes

tsebisa

Re hlahisa boqapi ba rona ba morao-rao ba lisebelisoa tsa ho seha, HSS end mill e nang le liphala tse 4! E etselitsoe ho kopana le litekanyetso tse phahameng ka ho fetisisa tsa ho nepahala le ho tšoarella, sesebelisoa sena sa morao-rao se reretsoe ho fetola indasteri ea machining.

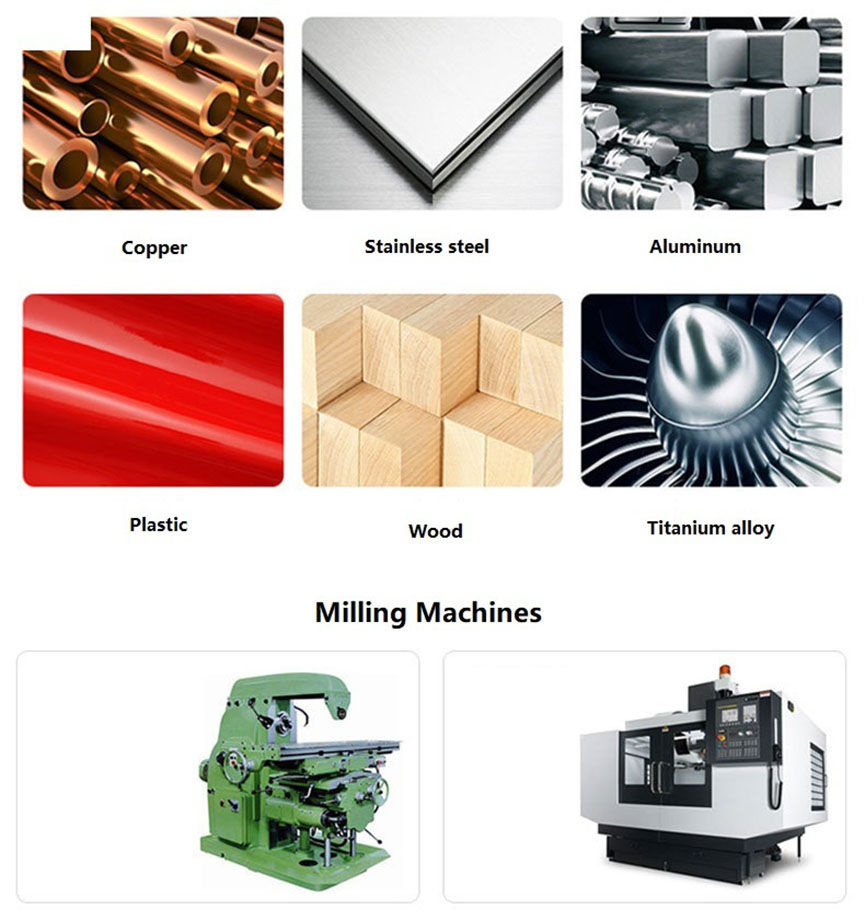

Bohareng ba leloala lena le tsotehang la ho qetela ho na le moralo oa eona o ikhethang oa 4-flute, o fanang ka ts'ebetso e phahameng ea ho itšeha le ntlafatso e ntlafalitsoeng ea ho ntša li-chip. Folute e 'ngoe le e 'ngoe e entsoe ka boqhetseke ho eketsa ts'ebetso e ntle, e lumellang ts'ebetso ea ho itšeha ka potlako le e boreleli mefuteng e mengata ea lisebelisoa, ho kenyeletsoa tšepe, aluminium le lisebelisoa tse ling. Geometry ea lekolilo e tsoetseng pele e boetse e fokotsa ho thothomela, e bakang bophelo bo ntlafalitsoeng ba lisebelisoa le tlhahiso e akaretsang.

E entsoe ka tšepe ea lebelo le phahameng (HSS), leloala lena la ho qetela le hahiloe ho mamella lits'ebetso tsa machining tse batloang haholo. Ka lebaka la ho hanyetsa mocheso o ikhethang, e khona ho sebetsana le ts'ebetso ea lebelo le phahameng le mocheso o phahameng ntle le ho sekisetsa ts'ebetsong kapa ho tšoarella. Ka boemo ba boima bo fetang litekanyetso tsa indasteri, leloala la rona la HSS le netefatsa ts'ebetso e tsitsitseng le ho nepahala ho ikhethang.

Ho feta moo, leloala la rona la ho qetela la HSS le na le lesela le khethehileng le ntlafatsang ts'ebetso le bophelo bo bolelele. Seaparo sena sa sejoale-joale se fokotsa likhohlano, se lumellang hore chip e tlosoe habonolo le ho fokotsa ho roala ha lisebelisoa. Ka ho roala hona, leloala la rona la ho qetela le boloka bohale ba lona esita le ka mor'a tšebeliso e telele, ho netefatsa liphello tse tsitsitseng le ho fokotsa nako ea ho phomola bakeng sa ho fetola lisebelisoa.

E 'ngoe ea melemo ea mantlha ea leloala la rona la HSS ke ho ikamahanya le maemo. Ho tloha ho ts'ebetso ho isa ho ho qetela, sesebelisoa sena se fana ka liphetho tse ikhethang lits'ebetsong tse fapaneng tsa machining, ho kenyelletsa le ho sila, ho slotting le contouring. Moralo oa eona o ntlafalitsoeng le tiisetso ea kaho ea boleng bo holimo e ntlafalitse ho nepahala le ho phethoa ha bokaholimo mefuteng e mengata ea lits'ebetso, e leng se ileng sa etsa hore e be khetho ea mantlha bakeng sa litsebi le batho ba ratang ho itlosa bolutu ka ho tšoana.

Ka leloala la ho qetela la HSS le nang le liphala tse 4, re ikemiselitse ho fa bareki ba rona sesebelisoa sa ho itšeha se kopanyang ts'ebetso e ikhethang, ho tšoarella, le ho feto-fetoha ha maemo. Hore na o indastering ea likoloi, ea sefofane, kapa indasteri ea mochini ka kakaretso, sesebelisoa sena se tiisitsoe hore se tla fana ka liphetho tse tsitsitseng, tse tšepahalang le ho feta litebello tsa hau.

E-ba le phapang eo HSS e qetellang e ka e etsa ts'ebetsong ea hau ea machining. Ntlafatsa lisebelisoa tsa hau tsa ho itšeha kajeno 'me u ntlafatse bokhoni ba hau ba ho sebetsa.

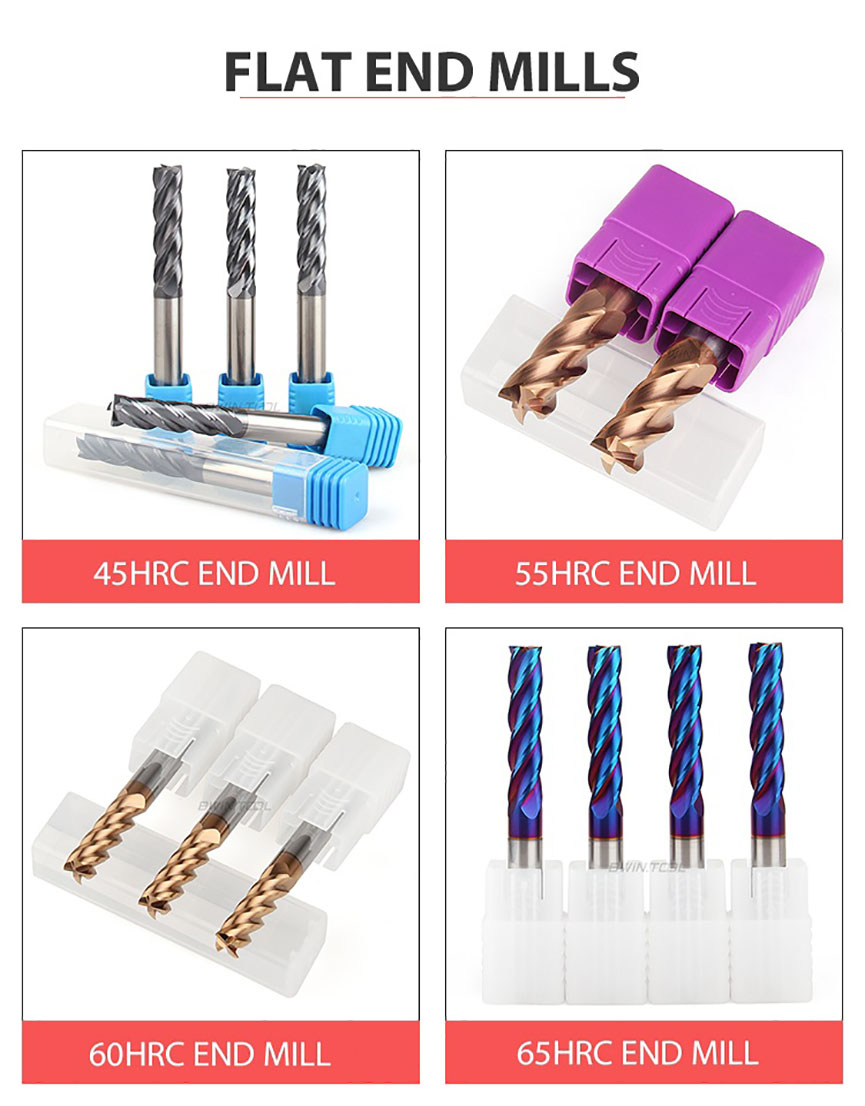

lintlha tsa hss end mill