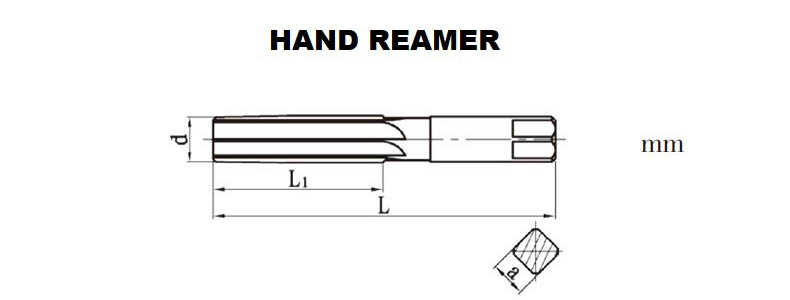

HSS Hand Reamer e nang le Flute e otlolohileng

HSS Hand Reamer DIN206 BS328/ISO236

| D | L | l | D | L | l |

| 5 | 87 | 44 | 23 | 215 | 107 |

| 5.5 | 93 | 47 | 24 | 231 | 115 |

| 6 | 93 | 47 | 25 | 231 | 1165 |

| 7 | 107 | 54 | 26 | 231 | 115 |

| 8 | 115 | 58 | 27 | 247 | 124 |

| 9 | 124 | 62 | 28 | 247 | 124 |

| 10 | 133 | 66 | 30 | 247 | 124 |

| 11 | 142 | 71 | 32 | 265 | 138 |

| 12 | 152 | 76 | 34 | 284 | 142 |

| 13 | 152 | 76 | 35 | 284 | 142 |

| 14 | 163 | 81 | 36 | 284 | 142 |

| 15 | 163 | 81 | 38 | 305 | 152 |

| 16 | 175 | 87 | 40 | 305 | 152 |

| 17 | 175 | 87 | 42 | 305 | 152 |

| 18 | 188 | 93 | 44 | 326 | 163 |

| 19 | 188 | 93 | 45 | 326 | 163 |

| 20 | 201 | 100 | 46 | 326 | 163 |

| 21 | 201 | 100 | 48 | 347 | 174 |

| 22 | 215 | 107 | 50 | 347 | 174 |

Likaroloana

1. Kaho ea Litšepe Tse Phahameng ka Ho Fetisisa: Lisebelisoa tsa letsoho tsa HSS li entsoe ka tšepe e phahameng ka potlako, thepa e thata le e tšoarellang e khonang ho mamella mocheso o phahameng le ho boloka ts'ebetso ea eona ea ho itšeha.

2. Moralo o otlolohileng oa Flute: Lisebelisoa tsa letsoho tsa HSS hangata li na le moralo o otlolohileng oa lekolilo, o lumellang ho ntša chip e boreleli le e sebetsang hantle. Sena se thusa ho thibela chip clogging kapa jamming nakong ea ho tsosolosa.

3. Precision Cutting: HSS hand reamers ke fatše ho tolerances ka thata ho etsa bonnete ba ho itšeha e nepahetseng le e nepahetseng. Li etselitsoe ho etsa masoba a boreleli, a nepahetseng, le a tebileng, ho ntlafatsa boleng le ho lekana ha mosebetsi.

4. Li-Reamers tsa letsoho tsa HSS li loketse ho sebelisoa mefuteng e mengata ea lintho, ho akarelletsa le litšepe tse fapa-fapaneng, lipolasetiki le lehong. Li ka sebelisoa mesebetsing ea ho cheka ka letsoho kapa ka lisebelisoa tsa motlakase tse tšoaroang ka letsoho.

5. Li-hand reamers tsa HSS li fumaneha ka mefuta e mengata e fapaneng ea boholo, ho kenyelletsa le litekanyo tse tloaelehileng tsa metric le tsa borena. Sena se lumella ho feto-fetoha ha maemo ha u khetha reamer e nepahetseng bakeng sa tlhokahalo e khethehileng ea boholo ba lesoba.

6. Li-reamer tsena hangata li na le shank e otlolohileng e ka ts'oaroang ka mokhoa o sireletsehileng ka har'a drill chuck, collet, kapa letsoho la sesebelisoa sa letsoho. Moqapi o otlolohileng oa shank o tiisa botsitso nakong ea ts'ebetso ea ho tsosolosa.

7. Lisebelisoa tsa letsoho tsa HSS li ka nchafatsoa, tsa lelefatsa bophelo ba tsona ba bohlokoa le ho fokotsa tlhoko ea ho nchafatsoa khafetsa. Sena se etsa hore e be khetho e theko e tlaase bakeng sa mesebetsi e pheta-phetoang ea ho tsosolosa.

8. Kaho ea tšepe e lebelo le phahameng e etsa hore li-reamers tsa letsoho tsa HSS li se ke tsa apara, li eketsa nako e telele le ho sebetsa ka kakaretso. Tlhokomelo e nepahetseng le lubrication li ka ntlafatsa nako ea bophelo ba tsona le ho feta.

9. Ts'ebetso e Tšoaretsoeng ka letsoho: Lisebelisoa tsa letsoho tsa HSS li etselitsoe haholo-holo ts'ebetso ea letsoho, e lumellang hore ho be le taolo e kholoanyane le ho nepahala. Li loketse hantle lits'ebetsong tsa setšeng kapa lithupelong moo mochini oa ho cheka o ka 'nang oa se fumanehe.

BONTŠA SEHLAHISO

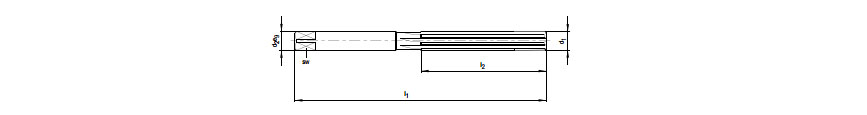

| Tlhaloso d | L1 | L | a |

| 3 | 31 | 62 | 2.24 |

| 4 | 38 | 76 | 3.15 |

| 5 | 44 | 87 | 4 |

| 6 | 47 | 93 | 4.5 |

| 7 | 54 | 107 | 5.6 |

| 8 | 58 | 115 | 6.3 |

| 9 | 62 | 124 | 7.1 |

| 10 | 66 | 133 | 8 |

| 11 | 71 | 142 | 9 |

| 12 | 76 | 152 | 10 |

| 13 | |||

| 14 | 81 | 163 | 11.2 |

| 15 | |||

| 16 | 87 | 175 | 12.5 |

| 17 | |||

| 18 | 93 | 188 | 14 |

| 19 | |||

| 20 | 100 | 201 | 16 |

| 21 | 100 | 201 | 16 |

| 22 | 107 | 215 | 18 |

| 23 | |||

| 24 | 115 | 231 | 20 |

| 25 | |||

| 26 |