HSS Milling Cutter e nang le meno a lifahleho tse 3

tsebisa

Li-cutters tsa mahlakore a mararo tsa HSS (High Speed Steel) ke lisebelisoa tse khethehileng tsa ho itšeha tse etselitsoeng lits'ebetso tse khethehileng tsa mochini. Tse ling tsa likarolo tsa bohlokoa tsa lithipa tsena li kenyelletsa:

1. Sesebelisoa se amohela moralo o ikhethang oa mahlakore a mararo a meno, o ka finyellang ho tlosoa ha thepa ka katleho le ho ntlafatsa ts'ebetso ea ho itšeha. Meno a mahlakoreng a mararo a etselitsoe ho fana ka ts'ebetso e ntlafalitsoeng ea ho itšeha le ho ntša li-chips.

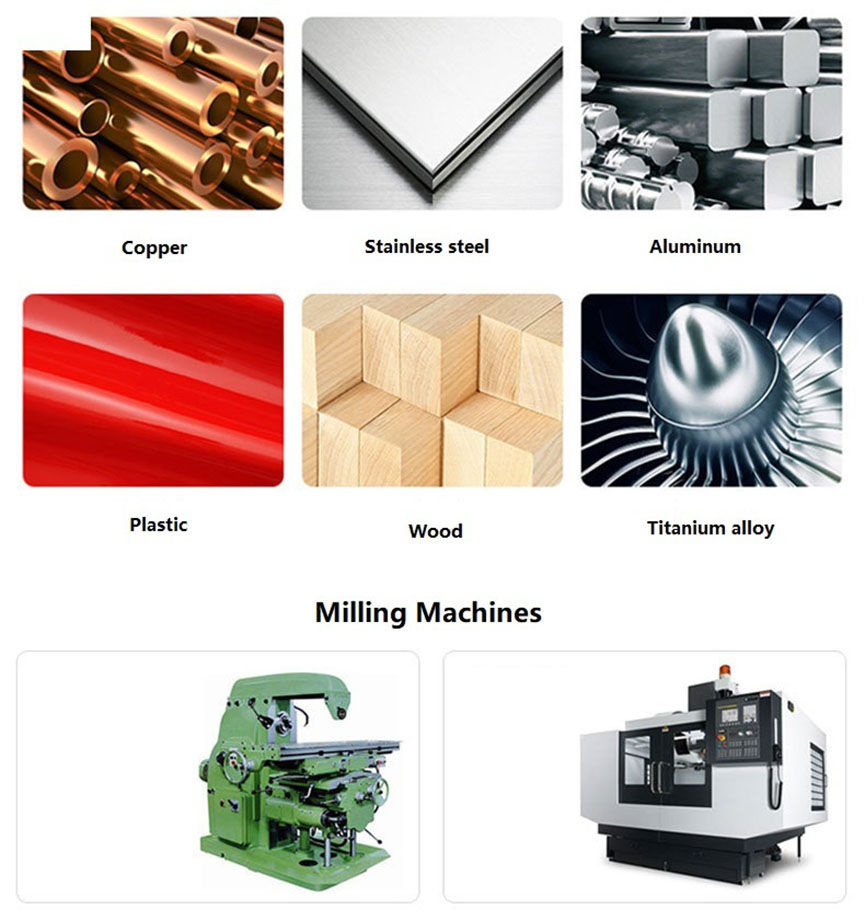

2. Li-cutters tsena tsa ho sila hangata li entsoe ka tšepe e phahameng ka potlako, e nang le khanyetso e ntle ea ho apara le ho tiea 'me e loketse ho khaola lisebelisoa tse sa tšoaneng, ho akarelletsa le tšepe, aluminium le li-alloys tse ling.

3. Hangata lisebelisoa li na le liphala tse ngata, tse thusang ho ntša li-chips tse sebetsang hantle le ho fana ka pheletso e ntle ea bokaholimo. Motsoako oa meno a mahlakoreng a mararo le moralo o nang le mahlakore a mangata o ntlafatsa bokhoni ba ho itšeha le bophelo ba lisebelisoa.

4. Lisebelisoa tsena li ka sebelisoa mesebetsing e fapaneng ea ho sila, ho kenyelletsa le grooving, profiling, le contouring, e leng ho etsang hore e tšoanelehe bakeng sa mefuta e fapaneng ea lisebelisoa tsa machining.

5. Moralo oa meno a mahlakoreng a mararo o nolofalletsa ho sebetsa ka mokhoa o nepahetseng le o nepahetseng, ho etsa bonnete ba hore boleng bo holimo ba boleng bo holimo le ho nepahala ha mahlakore.

6. Lisebelisoa tsena li etselitsoe hore li lumellane le mefuta e mengata ea mechine ea ho sila le litsi tsa machining, tse lumellang ho feto-fetoha ha mokhoa oa ho etsa lihlahisoa.

7. Li-cutters tsa tšepe tse lebelo tse phahameng li tsebahala ka ho hanyetsa mocheso, ho li lumella ho mamella mocheso o phahameng oa ho itšeha ntle le ho ama ts'ebetso.

8. Li-cutters tsa tšepe tse nang le mahlakore a mararo a lebelo le phahameng la tšepe li fumaneha ka boholo bo fapaneng ho ikamahanya le litlhoko tse fapaneng tsa ts'ebetso le ho fana ka phetoho bakeng sa likopo tse fapaneng tsa tlhahiso.

Ka kakaretso, seha sehalo sa tšepe se nang le mahlakore a mararo se nang le lebelo le phahameng ke sesebelisoa se ikhethileng se fanang ka ho nepahala, ho sebetsa hantle, le ho feto-fetoha ha mefuta e fapaneng ea ts'ebetso ea ho sila, e leng se etsang hore e be sesebelisoa sa bohlokoa liindastering tse fapaneng tsa machining le tsa tlhahiso.