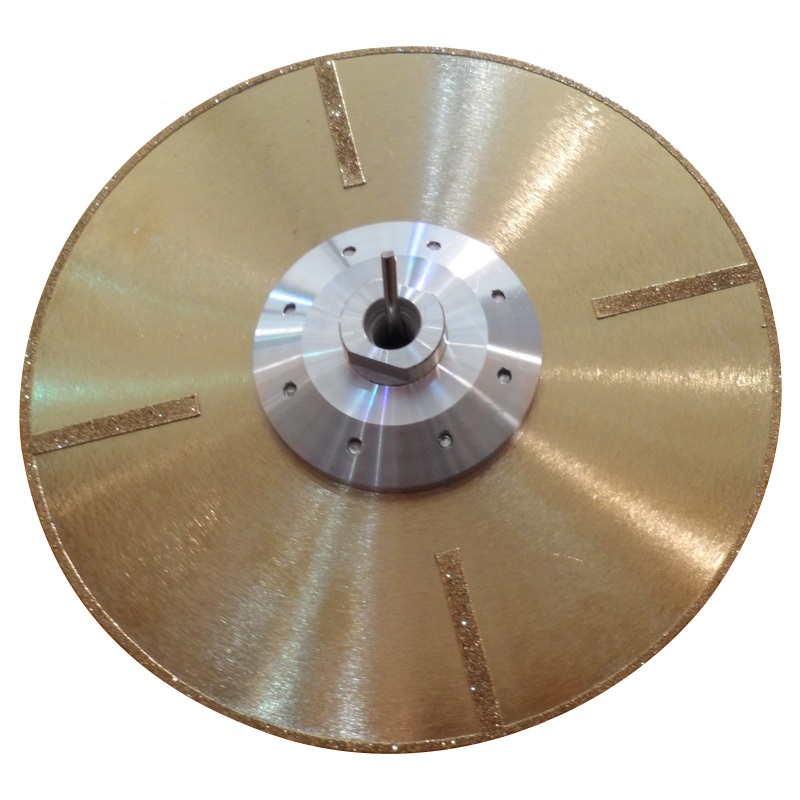

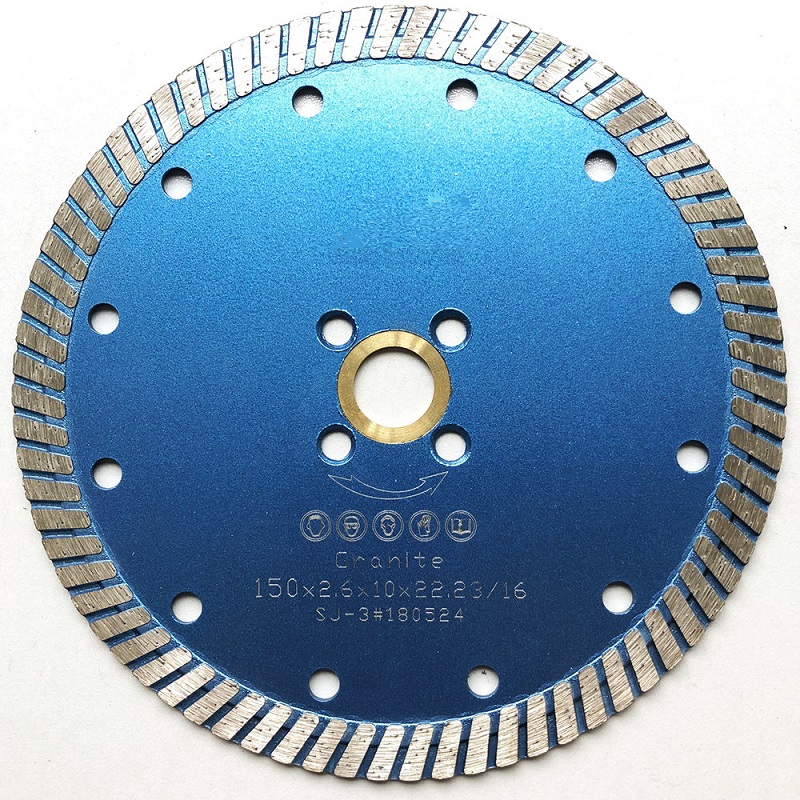

Laser Welded Circle Taemane Lehare la Bona

Likaroloana

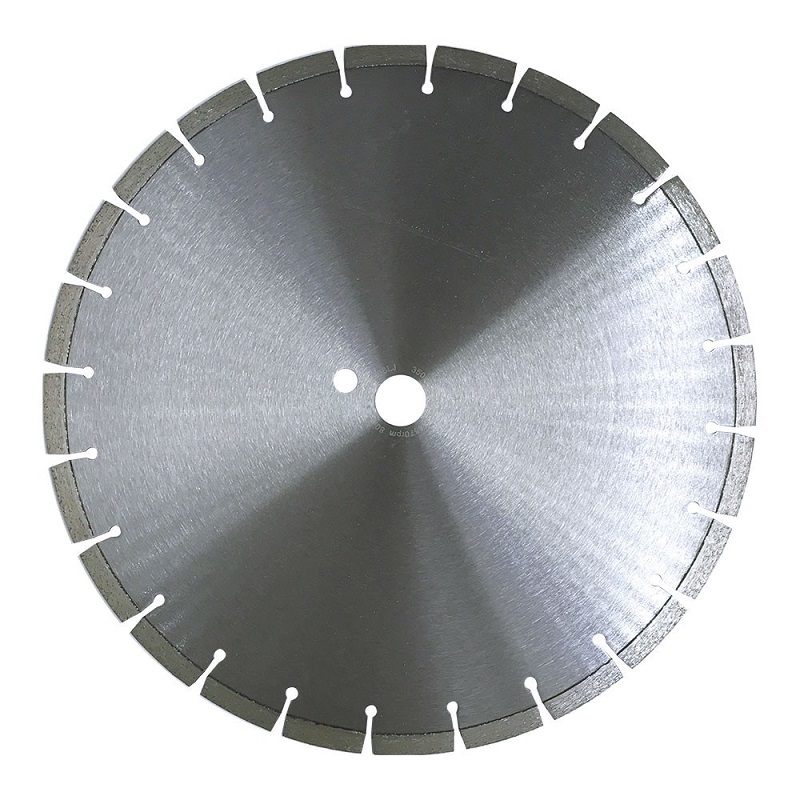

1. Likarolo tsa Laser Welded: Likarolo tsa daemane tsa laser welded circular saw blade li ts'oaretsoe ka nepo le ka mokhoa o sireletsehileng ho ea mantlha ho sebelisoa theknoloji e tsoetseng pele ea laser. Mokhoa ona oa ho kopanya o tiisa matla a holimo, botsitso le ho tšoarella.

2. Grit ea Taemane ea Boleng bo Phahameng: Likarolo tsa daemane tsa lehare la sakha li kentsoe ka grit ea boleng bo holimo ea taemane ea boemo ba indasteri. Sena se lumella ho itšeha ka potlako le ka mokhoa o atlehileng ka lisebelisoa tse fapaneng, ho kenyelletsa konkreite, asphalt, majoe le tse ling.

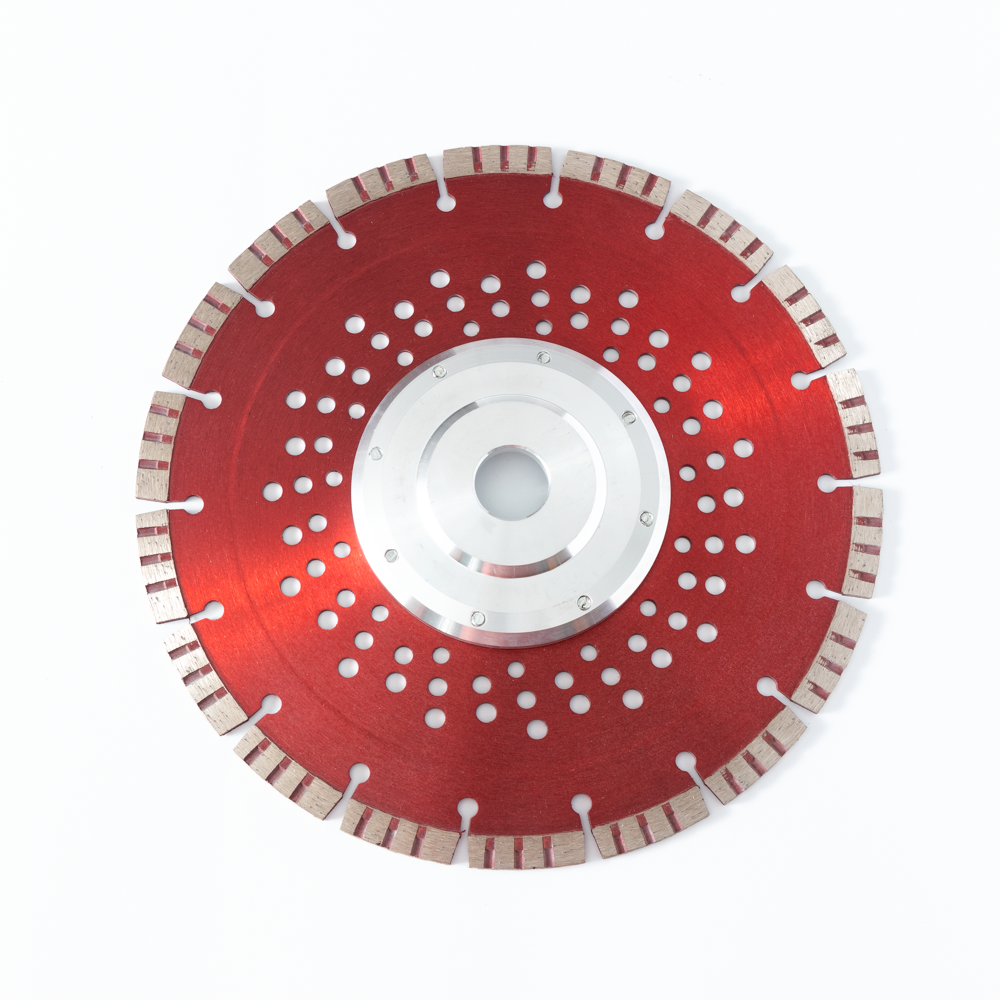

3. Heat Resistance: The laser welded bond e fana ka mocheso o babatsehang oa ho hanyetsa, o lumella lehare la saw ho mamella mocheso o phahameng o hlahisoang nakong ea ho itšeha. Sena se thibela mocheso o feteletseng le ho lelefatsa bophelo ba lehare.

4. Ho Seha ho Nepahetseng le ho Boreleli: Likarolo tsa daemane tse nang le laser-welded li entsoe ka ho nepahala le ho nepahala ho fana ka likotoana tse hloekileng le tse boreleli. Karolo ena e netefatsa liphetho tsa boleng ba profeshenale mme e fokotsa tlhoko ea ho qetela kapa ho belisoa.

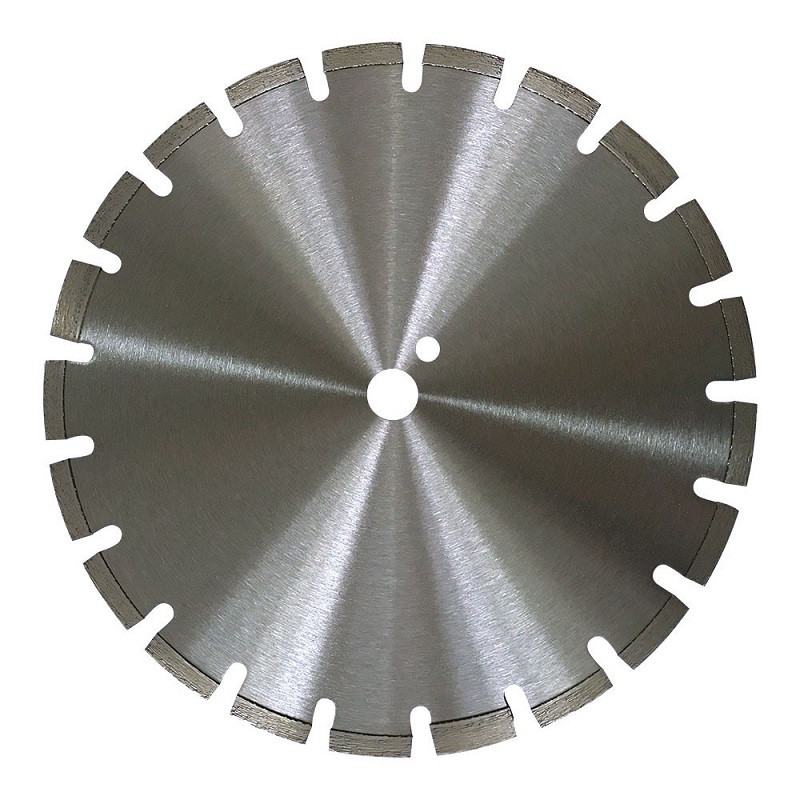

5. Ho Fokotsa Vibration le Lerata: Mokhoa oa welding oa laser o sebelisoang ha ho etsoa lehare le chitja la taemane le thusa ho fokotsa ho thothomela le lerata nakong ea ts'ebetso. Sena se lebisa ho boiphihlelo bo bonolo le bo bonolo ba ho itšeha.

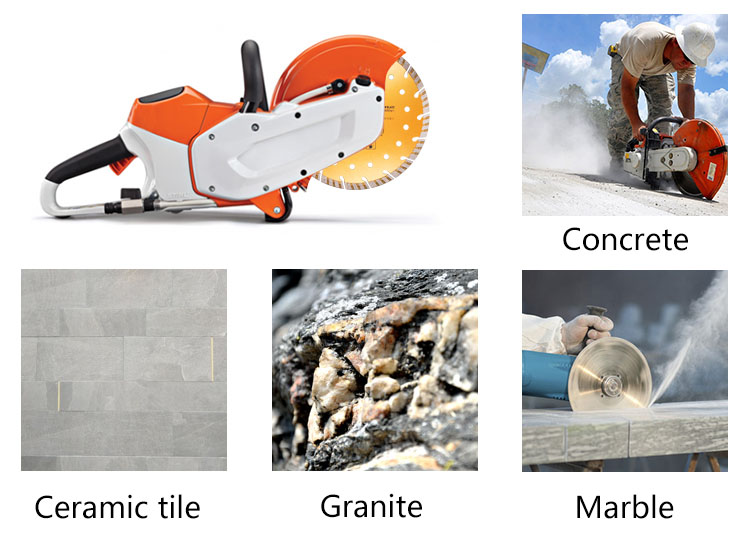

6. Versatility: Laser tjheseletsa selikalikoe di-blades daemane di tenyetseha 'me a loketse bakeng sa mefuta e fapaneng ya dikopo seha. Li ka sebelisoa ho khaola lisebelisoa tse fapaneng, ho kenyelletsa konkreite, masonry, litene, lithaele, granite le tse ling. Ho feto-fetoha hona ho li etsa sesebelisoa sa bohlokoa bakeng sa merero e fapaneng ea kaho le nchafatso.

7. Nako e Telele ea Bophelo: Khokahano ea laser welded e fana ka matla a ikhethang, e matlafatsang ho tšoarella ka kakaretso le nako ea bophelo ea lehare la sakha. Sena se lumella tšebeliso e atolositsoeng ntle le ho senya ts'ebetso ea ho itšeha.

8. Lebelo la ho Seha ka Potlako: Sekhahla sa boleng bo phahameng ba daemane le moralo o nepahetseng oa laser welded circular diamond saw blade e netefatsa ho itšeha ka potlako le ka katleho. Sena se boloka nako mme se eketsa tlhahiso sebakeng sa mosebetsi.

9. Ho lumellana le ho itšeha ho metsi le ho omme: Laser welded chitja diamant blades li etselitsoe ho sebelisoa bakeng sa ho seha metsi le omileng dikopo. Ho feto-fetoha ha maemo ho lumella basebelisi ho khetha mokhoa o loketseng ka ho fetisisa oa ho itšeha bakeng sa litlhoko tsa bona tse khethehileng le maemo a sebetsang.

10. Ho lumellana le Lisebelisoa tse sa tšoaneng tsa Matla: Laser welded circular diamond saw blades e lumellana le mefuta e mengata ea lisebelisoa tsa matla, ho akarelletsa le lisakha tse chitja, li-angles grinders, le lisakha tsa konkreite. Sena se etsa hore ho be bonolo ho se sebelisa mme se fana ka maemo a feto-fetohang khethong ea lisebelisoa.

Teko ea Sehlahisoa

sebaka sa tlhahiso