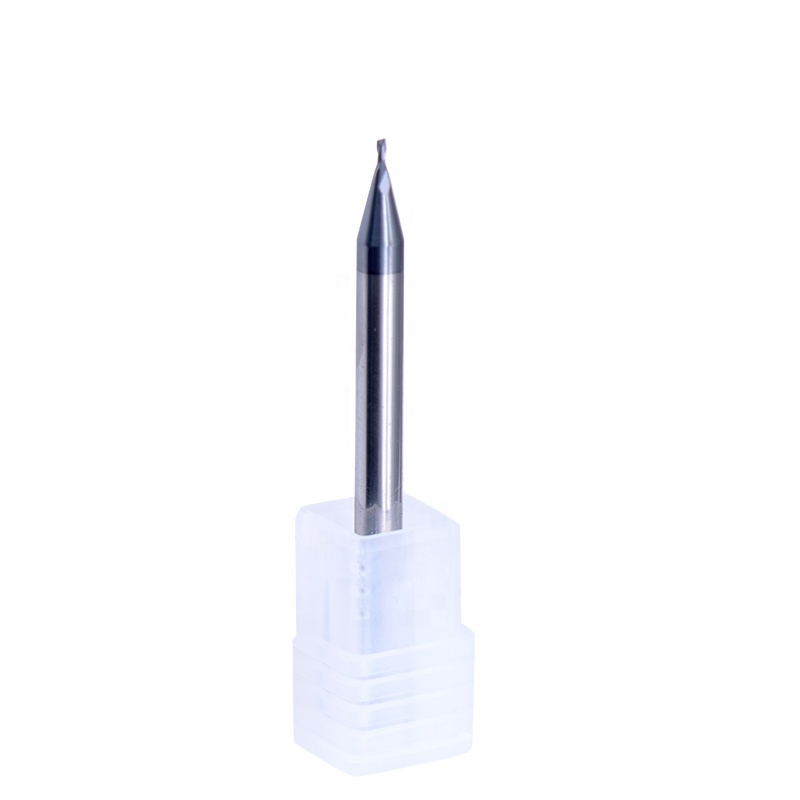

Micro Tungsten Carbide Square End Mill

Likaroloana

1. Bophara bo bonyenyane: Hangata liloala tse nyenyane li na le bophara bo tlohang ho 0.1mm ho ea ho 6mm, tse lumellang ho khaola ka mokhoa o nepahetseng le o rarahaneng libakeng tse thata. Sena se nolofalletsa ho lokisa lintlha tse ntle le likarolo tse nyane ka ho nepahala ho phahameng.

2. Boima bo phahameng: Tungsten carbide e tsejoa ka ho thatafala ha eona, e tiisang hore micro end mill e tšoarella le ho hanyetsa ho apara. Sena se etsa hore li tšoanelehe bakeng sa ho etsa lisebelisoa tse thata tse kang tšepe e sa hloekang, litšepe tsa lisebelisoa tse thata, le li-alloys tsa aerospace.

3. Mehato e bohale: Li-mill tse qetellang li entsoe ka likarolo tse bohale ho etsa bonnete ba ho khaola ho hloekileng le ho fokotsa kotsi ea tšenyo ea workpiece kapa burrs. Sena se bohlokoa bakeng sa lits'ebetso tse hlokang ho phethoa holimo holimo le ho nepahala ha sebopeho.

4. Phallo e sebetsang hantle ea li-chip: Moralo oa lekolilo oa li-micro end mill o ntlafalitsoe bakeng sa ho ntša li-chip, ho thibela chip buildup le ho netefatsa ts'ebetso ea ho itšeha hantle. Phallo e nepahetseng ea chip e thusa ho boloka ts'ebetso e ntle ea lisebelisoa le ho fokotsa monyetla oa ho senyeha ha lisebelisoa.

5. Mabotho a fokotsehileng a ho itšeha: Li-Mill end Mills li etselitsoe ho fokotsa matla a ho itšeha, e leng a bohlokoa haholo ha a sebetsa ka lisebelisoa tse bobebe kapa tse tšesaane. Matla a tlase a ho itšeha a thusa ho thibela ho kheloha ha li-workpiece le ho fokotsa monyetla oa ho roala kapa ho senyeha ha lisebelisoa.

6. Likhetho tsa ho roala: Lisebelisoa tsa ho qetela tsa li-tungsten carbide li ka fumaneha ka liaparo tse sa tšoaneng, tse kang TiAlN, TiSiN, kapa carbon-like carbon (DLC). Li-coating li eketsa ts'ebetso ea sesebelisoa ka ho fokotsa likhohlano, ho ntlafatsa ts'ebetso ea ho sesa, le ho fokotsa mocheso.

7. Likhetho tse ngata tsa lekolilo: Li-Mill end Mills li ka ba le 2, 3, kapa esita le liphala tse 4. Palo ea liphala e ama ho ntšoa ha chip le botsitso ba sesebelisoa nakong ea ho itšeha. Ho khetha moralo o nepahetseng oa lekolilo ho ipapisitse le ts'ebeliso e ikhethileng le lisebelisoa tse ntseng li etsoa.

8. Likhetho tsa Shank: Li-Mill end Mills li ka fanoa ka mefuta e sa tšoaneng ea shank, ho kenyelletsa le li-shank tse otlolohileng le li-tapered shanks. Khetho ea mofuta oa shank e itšetlehile ka sesebelisoa sa mochine le litlhoko tse khethehileng tsa ho seta mochine.

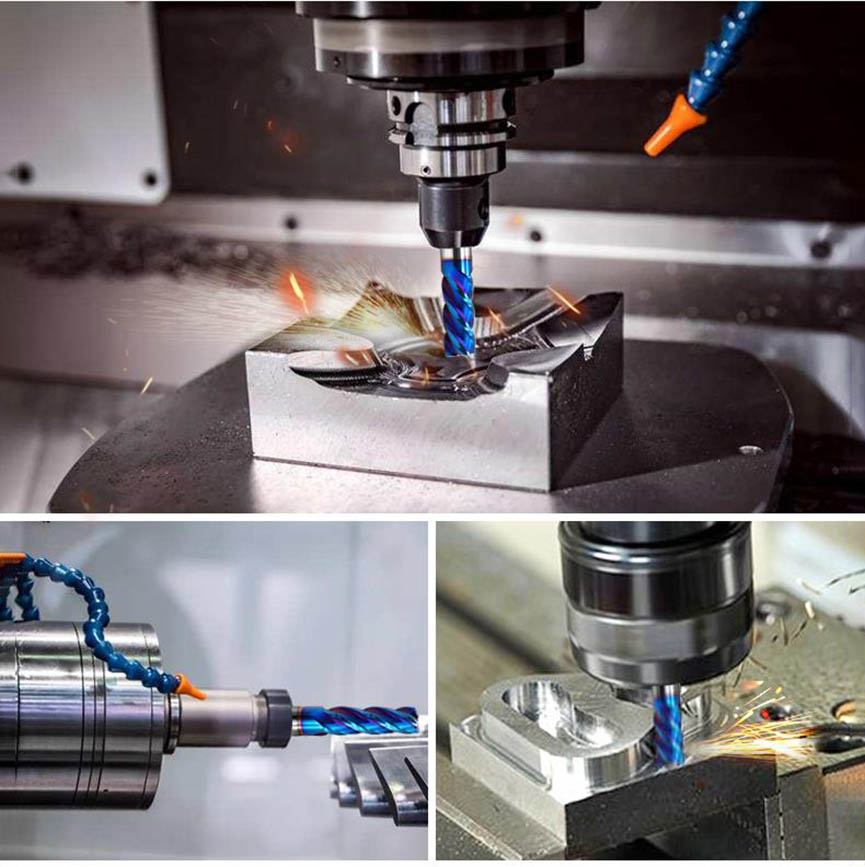

9. Ho feto-fetoha ha ts'ebeliso: Mechini ea ho qetela ea tungsten carbide e loketse mefuta e mengata ea lits'ebetso, ho kenyeletsoa machining a manyane, engraving, contouring le ho cheka. Li ka sebelisoa liindastering tse kang tsa elektroniki, tsa bongaka, tsa sefofane, le boenjiniere bo nepahetseng.

10. Likhetho tsa ho itloaetsa: Baetsi ba atisa ho fana ka lits'ebeletso tsa ho iketsetsa li-micro end Mills, tse lumellang bareki ho hlalosa bophara, bolelele ba lekolilo, bolelele ba kakaretso, ho roala le likarolo tse ling ho finyella litlhoko tsa bona tse khethehileng tsa machining.

boleng ba preminium tungsten carbide square end mill lintlha

fektheri

| 2 Flutes Micro End Mill | ||||

| Ntho | Flute Diameter(d) | Bolelele ba Flute(I) | Shank Diameter(D) | Kakaretso Bolelele(L) |

| 0.2*0.4*4*50 | 0.2 | 0.4 | 4 | 50 |

| 0.3*0.6*4*50 | 0.3 | 0.6 | 4 | 50 |

| 0.4*0.8*4*50 | 0.4 | 0.8 | 4 | 50 |

| 0.5*1*4*50 | 0.5 | 1 | 4 | 50 |

| 0.6*1.2*4*50 | 0.6 | 1.2 | 4 | 50 |

| 0.7*1.4*4*50 | 0.7 | 1.4 | 4 | 50 |

| 0.8*1.6*4*50 | 0.8 | 1.6 | 4 | 50 |

| 0.9*1.8*4*50 | 0.9 | 1.8 | 4 | 50 |