Morse Taper Shank HSS End Mills

Likaroloana

1. Morse Taper Shank: Leloala la ho qetela le na le shank e etselitsoeng hore e kene ka har'a mokokotlo oa Morse Taper. Sistimi ea Morse Taper e lumella ho hlongoa ho sireletsehileng le ho nepahetseng ha leloala la ho qetela mochining oa ho sila.

2. High-Speed Steel (HSS): HSS ke mofuta oa tšepe ea lisebelisoa tse atisang ho sebelisoa ha ho seha lisebelisoa. Li-mill tsa HSS li tsebahala ka ho tiea ha tsona, ho hanyetsa mocheso, le bokhoni ba ho mamella lebelo le phahameng la ho itšeha. Li-mill tsa HSS li loketse mefuta e mengata ea lisebelisoa, ho kenyeletsoa tšepe ea carbon, alloy steel, tšepe e sa hloekang, le litšepe tse se nang ferrous.

3. Likolutu: Leloala la ho qetela le tla ba le liphala tse ngata ka bolelele ba lona. Li-flute ke li-grooves tsa helical kapa tse otlolohileng holim'a leloala la ho qetela. Likolutu li thusa ho ntša li-chips le ho fana ka likarolo tse sehang bakeng sa ho tlosa thepa. Palo ea liphala e ka fapana ho latela ts'ebeliso, 'me likhetho tse tloaelehileng e le 2, 4, kapa 6 flutes.

4. Cutting Edge Geometry: Li-mill tsa HSS li tla ka li-geometri tse fapaneng, tse kang square end, ball nose, corner radius, kapa chamfer. Jiometry e 'ngoe le e' ngoe e loketse ts'ebetso e khethehileng ea ho sila le liphetho tse lakatsehang tsa bokaholimo.

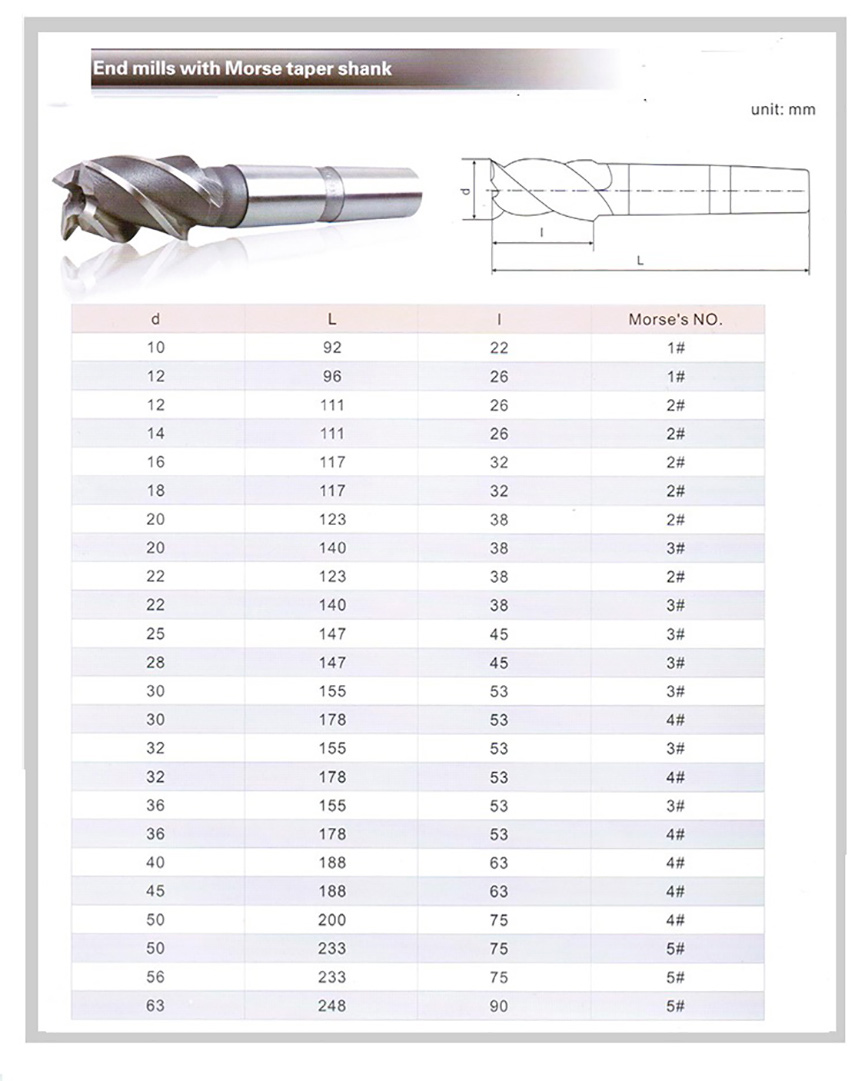

5. Bolelele ka Kakaretso le Bolelele ba Flute: Bolelele ka kakaretso bo bolela bolelele ba kakaretso ea leloala la ho qetela, ho tloha ntlheng ea ho itšeha ho isa qetellong ea shank. Bolelele ba lekolilo bo bolela bolelele ba karolo e sehang kapa phala. Bolelele bo fapaneng bo teng bakeng sa ho amohela botebo bo fapaneng ba milling le litlhoko tsa tumello.

6. Likhetho tsa ho Koaela: Mechini ea ho qetela ea HSS e kanna ea tla le likhetho tse fapaneng tsa ho roala joalo ka TiN, TiCN, kapa TiAlN. Liaparo tsena li fana ka khanyetso e ntlafetseng ea ho apara, ho eketsa bophelo ba lisebelisoa, le ts'ebetso e ntlafetseng lits'ebetsong tsa ho itšeha ka lebelo le phahameng kapa mocheso o phahameng.

7. Mefuta e Tloaelehileng: Morse Taper shank HSS end Mills e fumaneha ka boholo bo tloaelehileng bo lumellanang le lebitso la Morse Taper (MT1, MT2, MT3, joalo-joalo). Boholo bona bo netefatsa ho lekana hantle le ho tsamaellana le mechini e silang le li-spindle.

fektheri

Morse taper shank HSS end mill lintlha

Melemo

1. Ho Palama ho Sireletsehileng le ho Nepahetseng: The Morse Taper shank e fana ka sebaka se sireletsehileng le se nepahetseng ka har'a spindle, ho fokotsa ho phalla le ho netefatsa ho itšeha ho nepahetseng. Sena se thusa ho boloka ho nepahala ha dimensional le pheletso ea bokaholimo likarolong tse entsoeng ka mochini.

2. Versatility: Morse Taper shank HSS end Mills li fumaneha ka mefuta e fapaneng ya boholo le geometries, ho etsa hore ba a loketse bakeng sa tse sa tšoaneng milling tshebetso le mefuta e bonahalang. Ts'ebetso ena e fapaneng e lumella mefuta e mengata ea lits'ebetso ntle le tlhoko ea lisebelisoa tse ngata tsa lisebelisoa.

3. Ho tšoarella le ho hanyetsa mocheso: Li-mill tsa ho qetela tsa HSS li tsejoa ka ho ba thata le ho hanyetsa mocheso. Ba ka mamella lebelo le phahameng la ho itšeha le ho boloka ts'ebetso ea bona ea ho itšeha esita le tlas'a mocheso o matla o hlahisoang nakong ea ho sebetsa. Ho tšoarella hona ho fetolela bophelo bo bolelele ba lisebelisoa, ho fokotsa makhetlo a ho khutlisa lisebelisoa le nako ea ho thella ts'ebetsong ea mochini.

4. Chelete e Ntle: Li-mill tsa ho qetela tsa HSS hangata li na le litšenyehelo tse ngata ha li bapisoa le lisebelisoa tse ling tse sebetsang hantle, tse kang carbide. Li-mill tsa ho qetela tsa HSS li fana ka tekanyo e ntle pakeng tsa ts'ebetso le litšenyehelo, e leng se etsang hore e be khetho e nepahetseng bakeng sa mechine e tlaase ea molumo, lisebelisoa tse thata, kapa lisebelisoa tse nang le litlhoko tse fokolang haholo.

5. Ho lumellana: Morse Taper shank HSS end Mills e etselitsoe hore e lumellane le li-spindle tse tloaelehileng tsa Morse Taper tse atisang ho fumanoa mechineng ea ho sila. Khokahano ena e nolofatsa ho seta lisebelisoa, e fokotsa tlhoko ea li-adapter tse eketsehileng, 'me e lumella ho fapanyetsana habonolo lipakeng tsa lisebelisoa tse fapaneng.

6. Bokhoni ba ho Hlabolla Bocha: Li-mill tsa HSS li ka nchafatsoa habonolo, tsa lelefatsa bophelo ba tsona ba bohlokoa le ho fokotsa litšenyehelo tsa lisebelisoa ha nako e ntse e ea. Ka tlhokomelo e nepahetseng le ho chorisa, leloala la ho qetela la HSS le ka fana ka ts'ebetso e tsitsitseng le boleng ho feta lipotoloho tse ngata tsa machining.

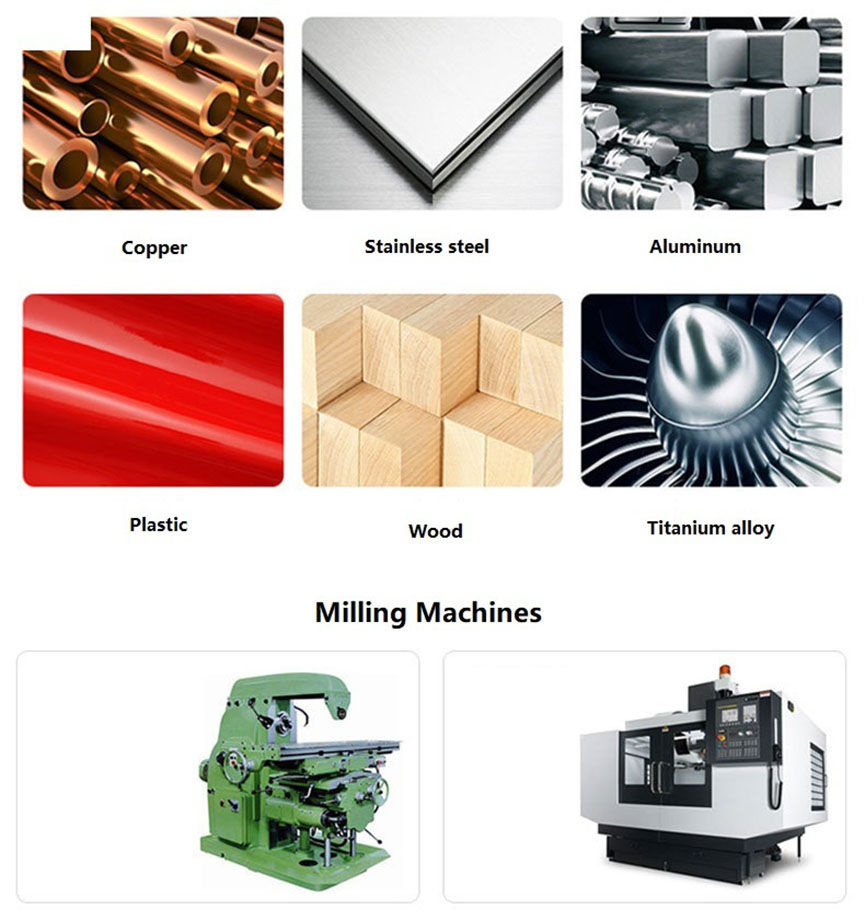

7. Wide Material Compatibility: Li-mill tsa ho qetela tsa HSS li ka sebetsa ka katleho mefuta e mengata ea lisebelisoa, ho akarelletsa le carbon steel, alloy steel, tšepe e sa hloekang, tšepe e entsoeng ka tšepe, litšepe tse se nang ferrous le polasetiki. Ho feto-fetoha hona ho etsa hore li tšoanelehe bakeng sa mefuta e fapaneng ea liindasteri le lits'ebetso.