Diamond Saw Blades: Tataiso e Feletseng ea Likarolo, Melemo, le Lintlha tsa Setegeniki

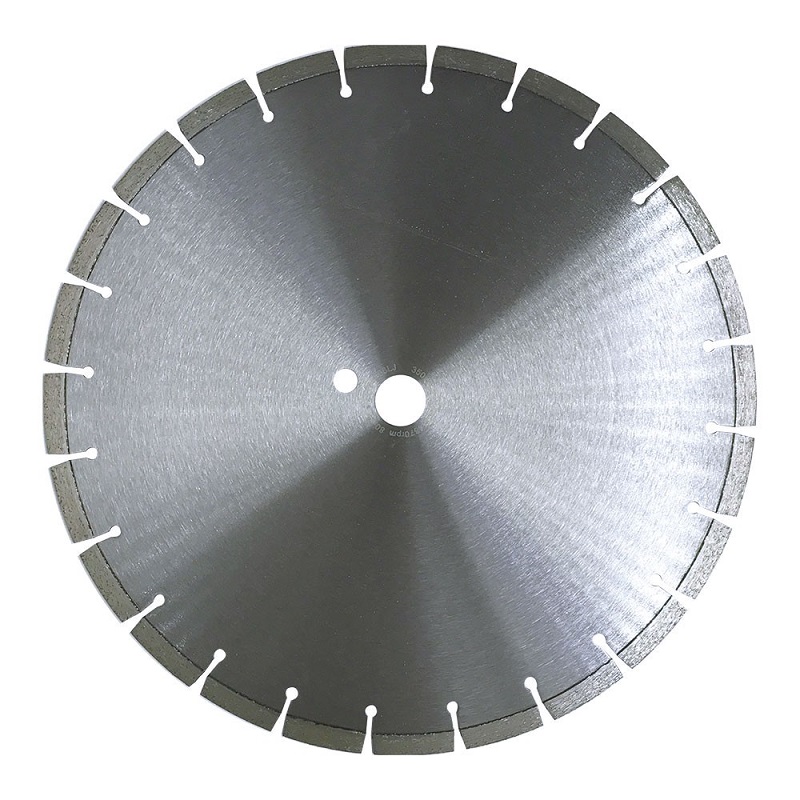

Likarolo tsa Bohlokoa tsa Li-Diamond Saw Blades

Tšebetso ea lehare la sakha ea daemane e itšetlehile ka moetso le kaho ea eona e ikhethang. Mona ke likarolo tsa bohlokoa tse hlalosang bokhoni ba eona:

1. Diamond Grit: The Cutting Powerhouse

Bohareng ba lehare le leng le le leng la daemane ke lehare la eona la daemane—litaemane tse nyenyane, tsa boemo ba indasteri tse kentsoeng moeling oa lehare. Litšobotsi tsa grit ena li ama ka kotloloho lebelo le ho nepahala:

- Boholo ba Grit: E lekantsoe ka letlooeng (mohlala, 30/40, 50/60), li-grits tse nyane (linomoro tse phahameng joalo ka 120/140) li hlahisa likheo tse boreleli, tse loketseng ho bentša kapa ho qeta. Li-grits tse kholoanyane (30/40) li khaola kapele empa li siea sebaka se makukuno, se loketseng mesebetsi e boima joalo ka ho pshatla konkreite.

- Taemane Concentration: E bolela palo ea litaemane ka cubic centimeter ka 'ngoe ea karolo ea lehare. Khokahano ea 100 (e tloaelehileng) e bolela 4.4 carats ea litaemane ka karolo. Lintho tse phahameng (120-150) li molemo bakeng sa lisebelisoa tse teteaneng tse kang granite, ha likhahla tse tlaase (75-80) li sebetsa bakeng sa lisebelisoa tse bonolo joaloka asphalt.

2. Likarolo tsa Blade le Bond

Mahare a daemane ha a tiile; li na le likaroloana (li-cutting dges) tse arohaneng ke likheo (tse bitsoang li-gullets) tse tlosang litšila. Bond ea karolo - thepa e tšoereng litaemane sebakeng - e lekanya ho tšoarella ha lehare le lebelo:

- Soft Bond: E etselitsoe lisebelisoa tse thata (mohlala, granite, khalase). Bond e fela ka potlako, e pepesa litaemane tse ncha ho boloka ts'ebetso ea ho itšeha

- Hard Bond: E loketse lisebelisoa tse bonolo, tse hlabang (mohlala, konkreite, litene). E hanela ho koaheloa, ho netefatsa hore litaemane li lula li kenelletse nako e telele

- Medium Bond: Khetho e feto-fetohang bakeng sa lisebelisoa tse tsoakiloeng joalo ka lejoe la mokoetla kapa 'mabole, lebelo la ho leka-lekanya le bophelo bo bolelele.

Likarolo li boetse li fapana ka sebopeho: likarolo tsa turbo (tse nang le mapheo a kobehileng) li khaoloa kapele, ha li-blades tse arohaneng (mets'o e otlolohileng) li ipabola ho tloseng lithōle tse boima.

3. Blade Diameter le Arbor Size

Li-blades tsa Diamond li tla ka bophara ba lisenthimithara tse 4 ho isa ho tse 48 ho lekana lisebelisoa tse fapaneng:

- Small Diameters (4-14 inches): E sebelisoa ka lithulusi tse tšoaroang ka letsoho tse kang li-angle grinders kapa lisakha tse chitja bakeng sa ho seha ka nepo lithaeleng kapa tšepeng.

- Li-Diameters tse kholo (16-48 inches): E behiloe holim'a lisakha tse tsamaeang ka morao kapa lisakha tsa fatše bakeng sa ho seha matlapa a konkreite, litsela kapa litene tse khōlō tsa majoe.

Boholo ba sekoti (sekoti se bohareng ba lehare) bo tlameha ho ts'oana le seluloana sa sesebelisoa. Mefuta e tloaelehileng e kenyelletsa 5/8 inch, 1 inch, le 20mm, ka li-adapter tse fumanehang bakeng sa boholo bo sa lumellaneng.

Melemo ea ho sebelisa li-Diamond Saw Blades

Diamond e ile ea bona li-blades li feta li-blades tsa setso hoo e batlang e le metric e 'ngoe le e' ngoe, e leng se etsang hore e be khetho e ka sehloohong bakeng sa mesebetsi e boima ea ho itšeha:

1. Lebelo le Sebetsang la ho Seha le sa Bapisoeng

Ho thatafala ha litaemane ho etsa hore mahare ana a phunyeletse ka har'a lisebelisoa tse thata joaloka konkreite kapa granite ka potlako ho feta carbide kapa li-blades tsa tšepe. Sena se fokotsa nako ea projeke - e bohlokoa bakeng sa litsebi tse sebetsang ka linako tse thata

2. Nako e telele le ho boloka litšenyehelo

Leha likhaba tsa daemane li na le litšenyehelo tse holimo, ho tšoarella ha tsona ho feta mefuta e meng e theko e tlase haholo. Lehare le le leng la daemane le ka rema konkreite e bolelele ba limithara tse makholo, athe lehare la carbide le ka 'na la hloka ho nkeloa sebaka ka mor'a limithara tse seng kae feela. Bophelo bona bo bolelele bo fokotsa litšenyehelo tsa nako e telele

3. Mefuta e sa tšoaneng ea Lintho Tse Ngata

Ho tloha ho tile ea ceramic ho ea ho konkreite e matlafalitsoeng, mahare a daemane a sebetsana le mefuta e mengata ea thepa ntle le ts'ebetso ea sehlabelo. Ho feto-fetoha hona ho felisa tlhoko ea li-blade tse ngata, ho nolofatsa lisebelisoa tsa lisebelisoa le ho fokotsa nako ea ho seta.

4. Ho nepahala le ho Hloeka ho Seha

Tsela e laoloang ea grit ea daemane e tiisa hore ho seha ho boreleli, ho nepahetseng, ho fokotsa ho petsoha kapa ho petsoha - ho bohlokoa bakeng sa mesebetsi e kang ho kenya lithaele kapa lejoe le sehang bakeng sa li-countertops. Ho nepahala hona ho fokotsa litšila le tlhoko ea ho bentša ka mor'a ho seha

Malebela a Theknoloji bakeng sa ho Sebelisa le ho Boloka Maqhubu a Saha a Taemane

Ho eketsa ts'ebetso le polokeho, latela litataiso tsena tsa tekheniki:

1. Operating Speed (RPM)

Lehare le leng le le leng la daemane le na le RPM e sireletsehileng ka ho fetisisa (lipotoloho ka motsotso) tse boletsoeng ke moetsi. Ho feta sena ho ka etsa hore lehare le chese ho feta tekano, le sothe kapa le robehe. Bapisa RPM ea blade le sesebelisoa sa hau:

- Lisila tse tšoaroang ka letsoho: 8,000–12,000 RPM (bakeng sa mahare a manyenyane).

- lisakha tse tsamaeang ka morao: 2,000–5,000 RPM (bakeng sa mahare a maholo).

Kamehla hlahloba buka ea litaelo ea sesebelisoa le leibole ea blade bakeng sa ho lumellana

2. Cooling le Lubrication

Mahare a daemane a hlahisa mocheso o matla nakong ea ho seha, o ka senyang lehare le thepa. Sebelisa metsi a pholileng (bakeng sa ho itšeha ka metsi) kapa ho ntša lerole (bakeng sa ho itšeha ka mokhoa o omileng) ho thibela mocheso o feteletseng:

- Wet Cutting: E hokela hose ea metsi sesebelisoa, ho fafatsa molapo o tsitsitseng holim'a lehare ho fokotsa khohlano le lerōle. E loketse merero ea ka tlung kapa ha ho nepahala ho le bohlokoa

- Dry Cutting: E sebelisa vacuum system ho tlosa litšila. E loketse mesebetsi ea ka ntle empa e hloka li-blades tse etselitsoeng ka ho khetheha bakeng sa tšebeliso e omileng (e ngotsoeng "dry cut").

3. Phahamiso e nepahetseng ea Lehare

Maqhubu a macha a daemane a hloka nako ea khefu ho netefatsa hore a senyehile. Qala ka ho khaola thepa e bonolo (joaloka asphalt) ka lebelo la halofo bakeng sa metsotsoana e 30-60, butle-butle e eketseha ka lebelo le feletseng. Sena se thibela ho pepeseha ha taemane ka tsela e sa leka-lekaneng le ho lelefatsa bophelo ba lehare

4. Tlhokomelo le Polokelo

- Hloekisa ka Mor'a Tšebeliso: Tlosa lithōle likarolong ka borashe ea terata ho thibela ho koala, e leng ho fokotsang bokhoni ba ho itšeha.

- Store Flat: Beha li-blades fatše kapa u li fanyehe ka ho toba ho qoba ho loana. Le ka mohla u se ke ua beha lintho tse boima holim'a tsona

- Hlahloba Kamehla: Sheba likarolo tse petsohileng, litaemane tse hlephileng, kapa li- warping. Li-blades tse senyehileng li lokela ho nkeloa sebaka hang hang ho qoba likotsi

Ho Khetha Lehare le Nepahetseng la Taemane bakeng sa Morero oa Hao

Ho khetha lehare le nepahetseng ho itšetlehile ka thepa le sesebelisoa:

- Konkreite kapa Masonry: Khetha lehare le arohaneng le nang le bond e thata le grit ea 30/40 bakeng sa ho itšeha kapele.

- Thaele kapa Khalase: Khetha ho ba le lehare le sa khaotseng le nang le grit e ntle (120/140) le bond e bonolo bakeng sa maqeba a boreleli, a se nang chip.

- Lejoe (Granite/Marble): Sebelisa lehare la turbo segment le nang le daemane e phahameng (120) le bond e mahareng.

- Tšepe: Khetha lehare le omeletseng le nang le bond e thata, e etselitsoeng ho seha ka har'a rebar kapa tšepe.

Nako ea poso: Aug-16-2025