The Precision Edge: Ho notlolla Matla a TCT Saw Blades ho Lisebelisoa tsa Kajeno tsa ho Seha

Ngaka ea Lintho Tse Ngata: Kamoo Teknoloji ea TCT e Fetolelang ho Seha

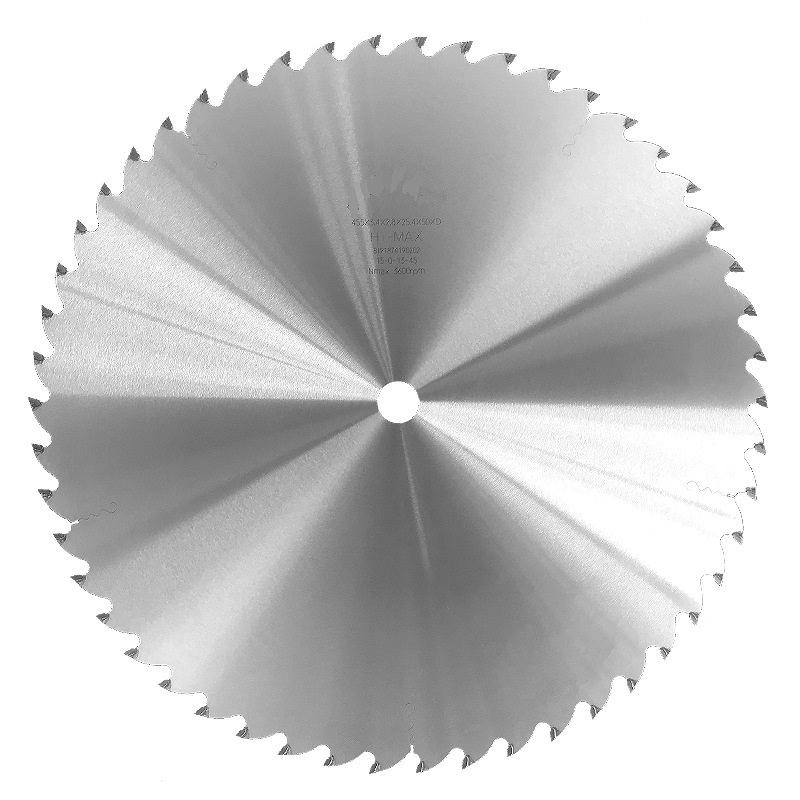

Li-blades tsa Tungsten Carbide Tipped (TCT) li emela tlhōrō ea theknoloji ea ho itšeha, e kopanyang ho nepahala ha opereishene le ho tšoarella ha indasteri. Ho fapana le li-blade tse tloaelehileng, TCT e kopanya meno a micro-grain tungsten carbide-e leng sehlopha se thata ka ho fetisisa se nang le litaemane - se khabisitsoeng kapa se tlanngoe holim'a 'mele ea tšepe e phahameng haholo. Moralo ona oa lebasetere o fana ka ts'ebetso e ke keng ea lekanngoa ho pholletsa le lehong, tšepe, metsoako, le lisebelisoa tse ikhethang, e leng se etsang hore e be 'mampoli ea ke keng a qojoa lithupelong tsa litsebi le maemong a indasteri lefatšeng ka bophara.

Core Engineering: The Anatomy of Peak Performance

1. Advanced Material Science

- Tungsten Carbide Teeth: E entsoe ka mefuta e fapaneng ea YG8-grade carbide kapa cobalt, malebela ana a boloka bohale bo bolelele ba 8-10x ho feta mahare a HSS, leha e seha mapolanka a thata (oak, teak) kapa tšepe e sa hloekang.

- Anti-Friction Coatings: Liaparo tsa PVD (Physical Vapor Deposition) holim'a li-blades tse kang letoto la NYX SS li fokotsa mocheso oa mocheso ka 40%, li thibela ho khomarela lintho tse bonahalang, le ho lelefatsa bophelo ba lehare 3x ka ho itšeha ka tšepe e sa hloekang.

- Shock-Absorbing Cores: Mele ea tšepe e thata haholo (HRC 65) e thibela ho loana nakong ea ts'ebetso ea torque e phahameng, e leng ea bohlokoa bakeng sa tšepe e sakhang e batang moo mocheso o fetang 600 ° F.

2. Lintlafatso tsa Geometri

- Litaba tsa Leino:

- Meno a Conical Scoring: Bakeng sa liphanele tsa laminate/veneer, meno a conical a theha maqhetsoana a se nang maqhetsoana ka libaka tsa pele tsa lintlha.

- Moralo oa Anti-Vibration: Likoluoa tsa spiral (15-25 ° helix angles) ka har'a mahare a lehong li thusa ho tsoa habonolo, ho fokotsa lerata ka 15 dB le ho tlosa ho thothomela ha sesebediswa.

- Oblique Clamping: Li-angles tse nang le tokelo ea molao tsa 45–90° ka har'a li-blade tse koetsoeng li matlafatsa botsitso, li fokotsa ho falla ha leino nakong ea ho seha litšepe tse boima.

3. Precision Balancing

- Khatello ea laser-calibrated e tiisa hore e sisinyeha ≤0.1mm, esita le ka bophara ba 660mm. Sena se thibela ho kheloha ha ho seha li-tubes tsa tšepe tse sa hloekang tse nang le marako a teteaneng, ho boloka mamello e sehiloeng ka har'a ± 0.2mm.

Melemo ea Ts'ebetso: Ho Feta Lebelo le Bophelo bo Bolelele

- Lintho Tse Fetohang

Letoto le le leng la letoto la NYX le fetoha ka mokhoa o se nang moeli pakeng tsa:- Litšepe: tšepe ea mohaho, aluminium (mahare a Bosun MAG350120L a khaola aluminium ho 3,000 RPM), le li-tubes tse sa hloekang.

- Likarolo tsa Lehong: Lifate tse thata, MDF le phenolic laminates ntle le ho taboha.

- Katleho ea Moruo

- E Eketsehile Bophelo ba Nako: 2–3x nako e telele ho feta li-blades tse tloaelehileng—lihora tse 20–24 holim’a red sandalwood vs. 8 hours for carbon steel .

- Poloko ea Matla: Jiometry ea meno e ntlafalitsoeng e fokotsa ho huloa ha motlakase ka 18% lits'ebetsong tse sehang ka serame.

- Boleng ba Bokaholimo le Polokeho

- Burr-Free Edges: Theknoloji ea ho itšeha ka mokhoa o batang e boloka lisebelisoa tsa mosebetsi li pholile, li thibela ho khopama ha mocheso le ho felisa ho qetela.

- Taolo ea Lerōle: Meetso ea lekolilo e tšoara 95% ea lithapo tsa patsi, e fokotsa likaroloana tse tsoang moeeng.

Litharollo tse Ikemetseng tsa Kopo: Li-blades tse Bapisang le Mesebetsi

Mosebetsi oa tšepe oa indasteri

- Thick-Section Steel: NYX DS PVD blades (660mm) e nang le meno a 180 a khaola li-billet tse tiileng ka 60-380 m / min. Pholiso e metsi e tlamehang.

- Stainless Tubing: Li-blade tsa CHAOS series (400mm) li sebelisa meno a 4 a TCT ho arola li-tubes tse nang le marako a masesaane (5mm min) ntle le ho putlama.

Woodworking & Composites

- Hardwood Bandsawing: TCT bandsaw seha oak ka 25 m/s—habeli lebelo la likhaba tsa khabone—ka ho chesa lefela.

- CNC Machining: Li-router bits tsa 25 ° spiral-angle li nolofalletsa 2x litefello tse potlakileng tsa lijo ho MDF carving vs. straight bits.

Ho Seha ho khethehileng

- Aluminium Fabrication: Maqhubu a meno a 120 (Bosun MAG350120L) a thibela ho lla ka meno a bevel a chenchana.

- Liphanele tse nang le Laminated: Li-blade tse feto-fetohang tsa lintlha li etsa likhefi tse bonolo tsa veneer tse tšesaane joalo ka 2.0mm.

Lethathamo: Tataiso ea Khetho ea Lehare la TCT ka Boitsebiso

| Mofuta oa Boitsebiso | Letoto la Letlapa | Lintlha tsa bohlokoa | Sekhahla se Fepang hantle |

|---|---|---|---|

| Ts'epe e sa beng le mabali | NYX SS PVD 6 | 180 meno, Ø225-660mm | 40–80 m/mots |

| Lehong le thata | TCT Spiral 5 | 15–25° helix, 0.45x core ratio | 8–12 m/min |

| Aluminium | Bosun MAG 8 | Meno a 120, Ø350mm | 25–40 m/min |

| Konkreite/ Boetsuwa ba ho boela | SDS Plus 2 | Malebela a 4-flute, YG8 carbide | 10–150 m/min |

Ho eketsa Bophelo ba Blade: Li-Protocols tsa Tlhokomelo

- Taeo e Phodileng: Li-emulsions tse qhibilihang ka metsi li tlameha ho itšeha ka tšepe; seha se ommeng se lumelletsoe feela bakeng sa lehong tlas'a botenya ba 20mm.

- Tlhahlobo ea Leino: Hlahloba ho robeha ha carbide lihora tse ling le tse ling tse 50 tsa ts'ebetso-fetola sebaka haeba ho phunyeha ho feta 0.3mm.

- Polokelo: E leketlile libakeng tse laoloang ke boemo ba leholimo; mongobo> 60% e potlakisa ho bola ha tšepe.

Bokamoso: Li-Blades tse bohlale le indasteri ea 4.0

Li-blade tsa TCT tsa mofuta o latelang li kentse li-chips tsa RFID ho latela ho khathala ha meno le lihora tsa ho itšeha, li hokahanngoa le litsamaiso tsa CNC bakeng sa litemoso tsa ho chorisa ka boits'oaro. Ho sa le joalo, liaparo tsa carbide tse nang le nano-layered (tlas'a nts'etsopele) li tšepisa 5x bophelo ba ho seha titanium.

Qetello: Ho nepahala joalo ka Maemo

TCT e ile ea bona li-blades li feta karolo ea tsona e le lisebelisoa feela tsa ho itšeha - ke litsamaiso tse hlophisitsoeng tse kopanyang metallurgy, geometry le dynamics. Ebang ke ho seha li-tubing tse sa hloekang ka mokhoa o nepahetseng oa boemo ba micron kapa ho betla lehong le thata ka bokhabane ba bonono, li fana ka katleho e ntle. Bakeng sa baetsi ba lihlahisoa ba batlang tlhahiso ea litšila kapa baetsi ba mapolanka ba batlang li-final-reading finishes, ho tsetela ho theknoloji e khethehileng ea TCT ha se taba ea boikhethelo - ke motheo oa mesebetsi ea matsoho ea tlhōlisano.

Nako ea poso: Jul-20-2025