The Ultimate Guide to Diamond Core Bits: Revolutionizing Precision Drilling Technology

Mefuta le Lihlopha tsa Diamond Core Bits

Mefuta le Lihlopha tsa Diamond Core Bits

Li-core bits tsa litaemane li tla ka litlhophiso tse fapaneng, e 'ngoe le e' ngoe e etselitsoe ho sebetsana le mathata a itseng a ho cheka le mefuta ea thepa. Ho bohlokoa ho utloisisa likarolo tsena bakeng sa ho khetha karolo e nepahetseng bakeng sa ts'ebeliso efe kapa efe e fanoeng.

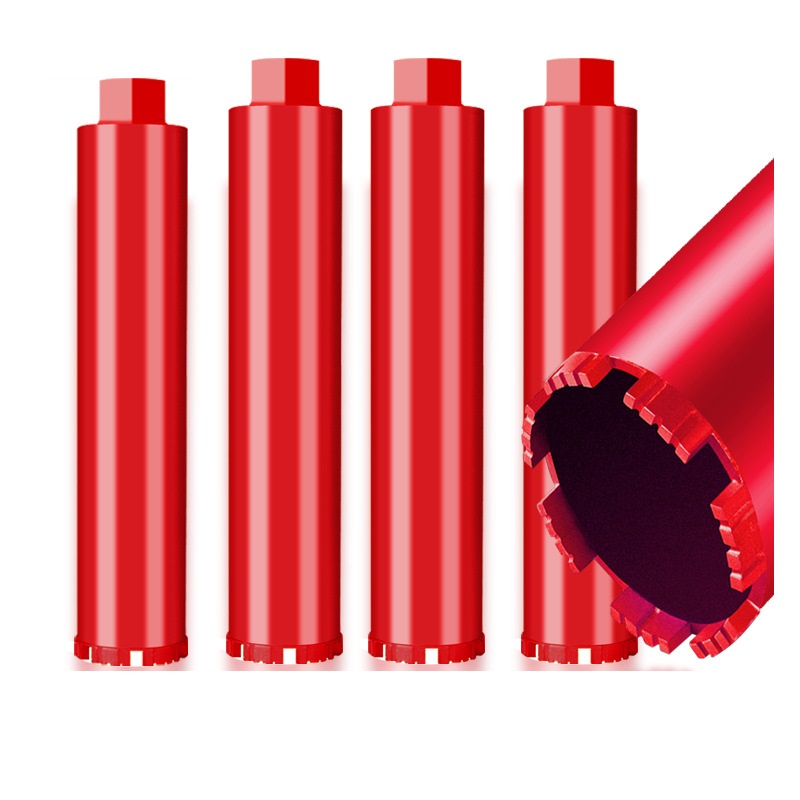

Dry vs. Wet Diamond Core Bits

E 'ngoe ea liphapang tsa mantlha likotong tsa mantlha tsa daemane ke mekhoa ea tsona ea ho pholisa. Lisebelisoa tsa motheo tsa daemane tse omileng, tse kang CorePlus CORDCDKIT7 sete, li etselitsoe ts'ebetso moo ho pholile ha metsi ho sa sebetseng kapa ho sa rateheng 1. Li-bits tsena hangata li na le 'mele oa li-ribbed core le likarolo tsa V-groove tse nolofalletsang ho tlosa litšila ka potlako, ho lumella ho tsoela pele ho khaola. Moralo oa mantlha o nang le moea o matlafatsang pholiso le ho lelefatsa bophelo ba mantlha, o etsa hore e be tse loketseng maemo a ho cheka holimo kapa moo ho sebetsoang lisebelisoa tse sa utloeng metsi.

Ka lehlakoreng le leng, likotoana tsa daemane tse metsi li hloka ho pholisoa ha metsi nakong ea ts'ebetso ho thibela ho futhumala ho feteletseng le ho lelefatsa bophelo ba karoloana. Likotoana tsena, tse kang 25-102mm laser-welded wet diamond core bits, li entsoe ka ho khetheha bakeng sa ho cheka konkreite e matlafalitsoeng 'me li fana ka bokhoni bo phahameng ba ho pholisa bo lumellang ho kenella ka botebo le ka potlako ho lisebelisoa tse thata.

Impregnated vs. Surface-Set Bits

Sehlopha se seng sa bohlokoa se khetholla pakeng tsa likotoana tsa mantlha tsa taemane tse kentsoeng le tse behiloeng holim'a metsi. Likotoana tse kentsoeng li na le litaemane tse ajoang hohle ka har'a matrix a bitana, joalo ka 61.5mm e kentsoeng ka daemane ea mantlha e etselitsoeng ho cheka lejoe le thata la granite 6. Ha matrix a ntse a senyeha nakong ea ts'ebetso, litaemane tse ncha li tsoela pele ho pepesoa, ho boloka ts'ebetso ea ho itšeha ha nyenyane ka nako e telele.

Li-bits tse behiloeng ka holim'a metsi li na le litaemane tse pepesitsoeng holim'a matrix, li fana ka liketso tse mabifi tsa ho itšeha tse loketseng lisebelisoa tse bonolo. Li-bits tsena hangata li fana ka lebelo la pele la ho itšeha empa li ka apara ka potlako ho feta meralo e kentsoeng lits'ebetsong tsa abrasive.

Mefuta e Khethehileng ea Moqapi

Ho hlahile meralo e fapaneng ea "diamane core bit" ho rarolla mathata a itseng a ho cheka:

- PDC (Polycrystalline Diamond Compact) bits: Likotoana tsena, tse nang le li-cutter tsa daemane tsa maiketsetso, li sebelisoa haholo lipatlisisong tsa oli le khase hammoho le mohlala oa geological core sampling 3. Li fana ka ts'ebetso e ikhethang le bokhoni ba ho itšeha ka bobeli bo bonolo le bo thata bo bohareng.

- Lisebelisoa tsa daemane ea Concave: Meralo e ncha e kang likotoana tsa StrataBlade li phahamisa li-cutters tsa geometry tse ikhethang tse nang le likarolo tse ikhethang tsa concave tse fokotsang sekhahla se sebetsang hantle sa "cutter back-rake angle", se nolofalletsang ho itšeha haholoanyane hore e be lejoe le hlabang le le nang le tšusumetso.

- Li-bits tse khethehileng tsa thaele: Likotoana tse khethehileng tsa daemane tse kang setulo sa Würth Diamond dry core bit M14 li entsoe ka ho khetheha bakeng sa ho cheka ka thepa ea ceramic e thata haholo ntle le ho pholile ha metsi.

Litlhaloso tsa Setsebi le Likarolo tsa Moqapi

Diamond core bits e kenyelletsa boenjiniere bo tsoetseng pele le litekanyetso tse nepahetseng tsa tlhahiso ho netefatsa ts'ebetso e nepahetseng lits'ebetsong tse fapaneng. Ho utloisisa lintlha tsa bona tsa tekheniki ho bohlokoa bakeng sa khetho e nepahetseng le ts'ebeliso.

Boleng ba Taemane le Tsepamiso

Ts'ebetso ea karoloana ea daemane ea mantlha e ipapisitse le boleng le bongata ba litaemane tse sebelisitsoeng kahong ea eona. Litaemane tsa boemo ba indasteri li khethoa ka hloko ho latela boholo, sebopeho, le litšobotsi tsa matla ho tsamaisana le litlhoko tse khethehileng tsa ho cheka. Ho ea ka maemo a DZ/T 0277-2015 bakeng sa likotoana tsa taemane tsa motheo tsa jeoloji, bahlahisi ba tlameha ho latela litataiso tse tiileng mabapi le boleng ba litaemane le kabo ho netefatsa ts'ebetso e ts'oanang.

Sebopeho sa Matrix

Matrix, kapa alloy ea tšepe e ts'oereng litaemane sebakeng sa eona, e phetha karolo ea bohlokoa ho khethollang litšobotsi tsa ts'ebetso. Matrix e tlameha ho etsoa enjene ho apara ka lebelo le laoloang le tsoelang pele ho pepesa litaemane tse ncha ha li ntse li boloka botšepehi ba sebopeho. Mefuta e fapaneng ea matrix e etselitsoe mefuta e ikhethileng ea sebopeho:

- Matrices a Soft formation: Thepa e bonolo ea bond e aparang kapele, e netefatsang hore daemane e pepeseha ka linako tsohle mekhoeng e sa senyeheng haholo.

- Li-matrices tsa sebopeho se thata: Libonto tse thata, tse sa senyeheng tse sireletsang ho bolokoa ha taemane libakeng tse hoholehang.

- Matrices a sebopeho se mahareng: Metsoako e leka-lekaneng e fanang ka ts'ebetso e phethahetseng mekhoeng e tsoakiloeng.

Bit Design le Geometry

Moralo oa 'mele oa likotoana tsa daemane o ama ts'ebetso ea bona haholo:

Letlapa: Likarolo tsa Moralo oa Diamond Core Bit le Mesebetsi ea Tsona

| Sebopeho sa Moralo | Mosebetsi | Mehlala ea Tšebeliso |

|---|---|---|

| Likanale tsa Metsi | Lumella pholiso ho phalla sebakeng se sehang | Lisebelisoa tsohle tsa ho cheka ka metsi |

| Bophahamo ba Karolo | E khetha bophelo bo fokolang le ho hanyetsa ho apara | Merero e telele ea ho cheka |

| Karolo ea Paterone | E ama lebelo la ho itšeha le ho tlosoa ha litšila | Mosebetsi oa kaho o potlakileng |

| Mofuta oa Khoele | E netefatsa ho lumellana le lisebelisoa tsa ho cheka | Litlhophiso tse tloaelehileng tsa ho cheka |

| Bophara ba Karolo | E susumetsa botsitso le ho seha mabifi | Litlhoko tsa ho cheka ka nepo |

Letoto la Husqvarna VARI-DRILL D25 DRY le bonts'a kamoo likarolo tsa moralo tse tsoetseng pele li ntlafatsang ts'ebetso, ka tlhophiso ea likarolo tse ikhethileng (botenya ba 3-4mm, bophahamo ba 9mm) e ntlafalitsoeng bakeng sa mefuta e fapaneng ea konkreite.

Litlhaloso tsa Boholo

Li-diamane core bits li fumaneha ka mefuta e mengata e fapaneng ea boholo ho lumellana le litlhoko tse fapaneng tsa ho cheka. Bophahamo bo tloaelehileng bo tloha ho li-diameter tse nyane (tse nyane joalo ka 1 inch/25mm bakeng sa mosebetsi o nepahetseng) 4 ho ea ho li-diameter tse kholo tse fetang 200mm bakeng sa merero e meholo ea kaho 7. Tekanyetso ea DZ/T 0277-2015 e totobatsa mamello e nepahetseng bakeng sa likotoana tsa ho cheka tsa jeoloji, ho netefatsa ho lekana le ts'ebetso e nepahetseng lits'ebetsong tsa litsebi.

Melemo le Melemo ea Diamond Core Bits

Bophahamo ba likotoana tsa mantlha tsa daemane ho feta mahlale a tloaelehileng a ho cheka bo bonahala likarolong tse ngata tsa ts'ebetso ea ho cheka, ho fana ka melemo e bonahalang ho litsebi ho pholletsa le indasteri.

Sebetsa se Ikhethang sa ho Seha le Lebelo

Taemane core bits e fana ka sekhahla sa ho kenella ka potlako haholo ha se bapisoa le likotoana tse tloaelehileng tsa ho cheka, haholo-holo ka thepa e thata le e boreleli. Ka mohlala, likarolo tsa daemane tsa StrataBlade concave diamond li bonts'itse keketseho e fihlang ho 28% ea sekhahla sa ho kenella (ROP) ha e bapisoa le liteko tse tloaelehileng tsa liteko tse entsoeng Haynesville Basin 10. Ts'ebetso ena e ntlafetseng e fetolela ka ho toba nako e fokotsehileng ea ho cheka le litšenyehelo tse tlaase tsa mosebetsi ka morero.

Ho nepahala le Boleng ba ho Seha

Ketso e ikhethang ea ho itšeha ea likotoana tsa daemane tsa mantlha e hlahisa masoba a hloekileng, a nepahetseng a nang le tšenyo e nyane kapa tšenyo ea thepa. Ho nepahala hona ho bohlokoa haholo lits'ebetsong tseo ho tsona geometry ea lesoba le mabota a mahlakore a boreleli li leng bohlokoa, joalo ka lipeiping tsa metsi, tsa motlakase le tsa HVAC mererong ea kaho. Likotoana tse ikhethileng joalo ka Würth Diamond dry core bits li entsoe ka ho khetheha ho thibela tšenyo ea thepa e bonojoana joalo ka lithaele tsa ceramic ha li ntse li fana ka masoba a hloekileng.

Nako e telele le litšenyehelo tse sebetsang hantle

Leha a na le litšenyehelo tse phahameng tsa pele, li-diamond core bits li fana ka boleng bo ikhethang ba nako e telele ka bophelo bo atolositsoeng ba ts'ebeletso le ho fokotsa makhetlo a mangata. The impregnated taemane konokono likotoana entsoe ke lik'hamphani tse kang Hunan Diyfia li etselitsoe ho tsoela pele ho pepesa litaemane foreshe e le matrix apara, ho boloka ho itšeha bokgoni ho pholletsa le hanyenyane bophelo ba 6. durability Sena se etsa hore ba haholo-holo e ka bolokang chelete e ngata bakeng sa mesebetsi e meholo ea ho cheka moo liphetoho tse nyenyane hangata li neng li tla ama haholo tlhahiso.

Mefuta-futa ea Lintho Tse Ngata

Lithako tsa daemane tsa mantlha li bonts'a ho tenyetseha ho makatsang, tse khonang ho cheka ka har'a lisebelisoa tse ngata tse kenyelletsang:

- Konkreite ea konkreite le e matlafalitsoeng: Tšebeliso e tloaelehileng mohahong

- Majoe a tlhaho le masonry: Ho kenyeletsoa granite, 'mabole le lejoe la mokoetla

- Lithaele tsa Ceramic le porcelain: Likotoana tse khethehileng tse omeletseng li thibela ho phatloha

- Asphalt le lisebelisoa tse kopaneng: Ka meralo e ikhethang

- Geological formations: Bakeng sa sampole ea mantlha ha ho hlahlojoa

Mokhathala o Fokotseng oa Opereishene

Ketso e sebetsang hantle ea ho seha ha likotoana tsa daemane tsa mantlha e hloka khatello e tlase e tlase mme e hlahisa ho thothomela ho fokolang ha ho bapisoa le mekhoa e tloaelehileng ea ho cheka. Phokotso ena ea khatello ea 'mele e fana ka mokhathala o fokotsehileng oa basebetsi, haholo-holo nakong ea ho cheka nako e telele kapa ha u sebetsa ka holimo. Li-ergonomics tse ntlafalitsoeng li kenya letsoho ho hlahiseng tlhahiso e phahameng le ho ntlafatsa polokeho ea sebaka sa mosebetsi.

Lisebelisoa le Tšebeliso ea Diamond Core Bits

Li-diamond core bits li sebeletsa mesebetsi ea bohlokoa ho pholletsa le liindasteri tse fapaneng, e 'ngoe le e' ngoe e na le litlhoko tse ikhethang tse phahamisang bokhoni bo ikhethang ba lisebelisoa tsena tse tsoetseng pele.

Indasteri ea Kaho le Kaho

Lefapheng la kaho, likotoana tsa mantlha tsa daemane li bohlokoa haholo bakeng sa ho theha menyetla e nepahetseng bakeng sa lits'ebeletso, lits'ebetso tsa HVAC, lipeipi tsa metsi le likotopo tsa motlakase. Bokhoni ba bona ba ho khaola ka konkreite e matlafalitsoeng ntle le ho senya botšepehi ba sebopeho sa thepa e potolohileng bo etsa hore e be ba bohlokoa ka ho khetheha bakeng sa merero ea ho nchafatsa le ho khutlisa chelete. Lisebelisoa tsa daemane tse metsi tse 25-102mm laser-welded wet core ke mohlala oa lisebelisoa tse ikhethileng tse etselitsoeng lits'ebetso tsena, tse fanang ka ho cheka ka lebelo le phahameng ho nang le litholoana tse hloekileng ka konkreite le konkreite e matlafalitsoeng.

Indasteri ea Oli le Khase

Lekala la petroleum le itšetlehile haholo ka theknoloji e tsoetseng pele ea taemane ea mantlha bakeng sa lipatlisiso le ho cheka tlhahiso. Li-bits tsa PDC li se li atile haholo lits'ebetsong tsa sebaka sa oli ka lebaka la ts'ebetso ea tsona e telele ea nako e telele le ts'ebetso e ntle ea ho cheka ha li bapisoa le likotoana tsa khale tsa rolara. Litlhahiso tsa morao-rao tse kang likaroloana tsa daemane tsa StrataBlade concave li bonts'itse lintlafatso tse kholo ts'ebetsong ea ho cheka, ka liteko tsa masimong ho pholletsa le likotlolo tse kholo tsa shale tse bonts'ang ntlafatso e tsitsitseng ea ROP.

Lisebelisoa tse khethehileng

Ka ntle ho liindasteri tsena tse kholo, lisebelisoa tsa daemane tsa mantlha li sebetsa mesebetsi e mengata e ikhethang:

- Ho etsoa ha semiconductor: Nts'etsopele ea liphaephe tsa taemane tsa 100mm tsa kristale e le 'ngoe e emela katleho e ka fetolang tsamaiso ea mocheso ho lisebelisoa tsa elektronike tse nang le matla a phahameng 9. Le hoja e se ts'ebeliso ea ho cheka ka se seng, mokhoa ona o mocha o bontša bokhoni bo ntseng bo eketseha ba theknoloji ea daemane.

- Mosebetsi oa lithaele le masonry: Likotoana tse khethehileng tsa daemane tse kang letoto la Würth M14 li thusa litsebi ho etsa masoba a phethahetseng ka thepa e boreleli ea ceramic ntle le ho pholile ha metsi, ho thibela tšenyo ea libaka tse felileng.

- Nts'etsopele ea meaho: Lithako tse kholo tsa litaemane li bohlokoa bakeng sa ho bula menyetla ea lits'ebeletso, lits'ebetso tsa likhoerekhoere le libaka tsa phihlello mererong e meholo ea meralo.

Litaelo tsa Khetho le Malebela a Tšebeliso

Ho khetha karolo e nepahetseng ea daemane ea mantlha bakeng sa ts'ebeliso e itseng ho hloka ho shebisisa lintlha tse ngata ho netefatsa ts'ebetso e nepahetseng le ho boloka litšenyehelo.

Tekolo ea Tšebelisano ea Lintho

Mohato oa pele oa ho khetha sekoahelo sa daemane se kenyelletsa ho khetholla thepa ea mantlha e lokelang ho chekoa. Lisebelisoa tse fapaneng li hloka meralo e ikhethileng le meralo ea litaemane:

- Konkreite e bonojoana le setene: Likotoana tse tloaelehileng tse setehileng holim'a metsi tse nang le taemane e pepesehileng haholoanyane

- Konkreite e matlafalitsoeng: Likotoana tse thata-thata tse hanyetsanang le mocheso bakeng sa ho matlafatsa tšepe

- Abrasive sandstone: Likotoana tse kenngoeng ka mokhoa o tšoarellang oa matrix

- Ceramic le porcelain: Likaroloana tsa daemane tse ntle tsa grit tse nang le moralo o ikhethileng oa karolo

Tlhahlobo ea Tšebelisano ea Lisebelisoa

Ho netefatsa tšebelisano lipakeng tsa "diamane core bit" le lisebelisoa tsa ho cheka ho bohlokoa bakeng sa polokeho le ts'ebetso. Lintlha tsa bohlokoa li kenyelletsa:

- Tšebelisano ea mofuta oa khoele: Likhokahano tse tloaelehileng li kenyelletsa 1/2″ BSP, M14, M16, le 5/8″-11 thread 18

- Litlhoko tsa matla a lisebelisoa: Ho netefatsa torque e lekaneng le bokhoni ba RPM

- Ho lumellana ha tsamaiso ea ho pholisa: Ho kopanya likotoana tse metsi / tse omeletseng le lisebelisoa tse loketseng

Mekhoa e metle ea ho sebetsa

Ts'ebetso e nepahetseng e eketsa bophelo bo fokolang haholo mme e netefatsa ts'ebetso e nepahetseng:

- Pholiso e lekaneng: Ho boloka metsi a phallang hantle bakeng sa likotoana tse metsi kapa linako tse loketseng tsa ho cheka bakeng sa likotoana tse omeletseng.

- Optimal pressure: Ho sebelisa khatello e lekaneng bakeng sa ho itšeha hantle ntle le matla a feteletseng a bakang mocheso o feteletseng

- Ho hlwekisa kgafetsa: Ho tlosa maloanlahla mekoting le dikarolong tse nyane ho thibela ho thibana

- Litokiso tsa lebelo: Ho fetola RPM ho ipapisitse le boima ba thepa le bophara ba hanyane

Tlhokomelo le Polokelo

Tlhokomelo e nepahetseng e eketsa bophelo ba "diamane core bit" mme e boloka ts'ebetso ea ho itšeha:

- Ho hloekisa ka botlalo ka mor'a ts'ebeliso e 'ngoe le e' ngoe ho tlosa litšila likarolong

- Ho boloka ka nepo maemong a ts'ireletso ho thibela tšenyo ea taemane

- Ho hlahlojoa khafetsa bakeng sa ho senyeha ha karolo kapa tšenyo pele ho ts'ebeliso e 'ngoe le e 'ngoe

- Mekhoa ea ho chorisa bakeng sa likotoana tse kenngoeng ha ts'ebetso e fokotseha

Litlhahiso le Mekhoa ea Bokamoso ho Diamond Core Bit Technology

Indasteri ea mantlha ea litaemane e ntse e tsoela pele ho fetoha, 'me lipatlisiso tse tsoelang pele le nts'etsopele li tsepamisitse maikutlo ho ntlafatseng ts'ebetso, ho holisa lits'ebetso le ho fokotsa litšenyehelo.

Lisebelisoa tse Tsoetseng Pele le Tlhahiso

Khatelo-pele ea morao-rao ea mahlale a lintho tse bonahalang e lebisitse ntlafatsong e kholo ea theknoloji ea "diamane core bit". Nts'etsopele ea litaemane tsa maiketsetso tsa premium-grade tse nang le thepa e laoloang ka hloko e nolofalelitse bahlahisi ho ntlafatsa mahloriso a litaemane le kabo bakeng sa lits'ebetso tse ikhethileng. Ho feta moo, lintlafatso tsa mekhoa ea tšepe le litaemane/tšepe li entse hore ho be le lisebelisoa tse tšoarellang tsa matrix tse lelefatsang bophelo ka har'a mekhoa e thata.

Geometry e khethehileng le Hydraulics

Baetsi ba li-Bit ba ntse ba shebana haholo le meralo e ntlafalitsoeng ea hydraulic e ntlafatsang ho pholisa le ho tlosa litšila, ho ntlafatsa bokhoni ba ho cheka le bophelo bo fokolang. The StrataBlade concave diamond element element e nang le geometry ea bona e ikhethang e emela mokhoa ona, o nang le moralo o ikhethang oa concave o fokotsang sekhahla se sebetsang sa "back-rake angle" bakeng sa ho kenella ka botebo.

Ho kopanya le Digital Technologies

Bokamoso ba thekenoloji ea "diamane core bit" e kenyelletsa ho kopanya ho hoholo le litsamaiso tsa dijithale bakeng sa ho lekola le ho laola ka nepo. Sistimi e bohlale ea ho cheka e fetolang liparamente ka nako ea 'nete e ipapisitseng le maikutlo a sebopeho e ntse e ata haholo, haholo ts'ebelisong ea oli le khase. Litsamaiso tsena li ntlafatsa ts'ebetso e nyane le ho thibela tšenyo ka ho ikamahanya le maemo a fetohang nakong ea ts'ebetso ea ho cheka.

Mehopolo ea Tikoloho le Bokhabane

Khatello e ntseng e hola ea ts'ebetso e ntse e tsoela pele ho ntlafatsa mahlale a ho cheka a baballang matla. Li-diamane core bits li kenya letsoho lipakaneng tsena ka ho fokotsa nako ea ho cheka le tšebeliso e tlaase ea matla ha e bapisoa le mekhoa e tloaelehileng. Ho feta moo, nts'etsopele ea lits'ebetso tsa ho cheka tse omeletseng tse felisang ts'ebeliso ea metsi e rarolla mathata a tikoloho libakeng tse sa utloeng metsi ha e ntse e boloka ho cheka hantle.

Qetello: Bokamoso ba ho Cheka ka Diamond Core Bits

Li-diamond core bits li itlhomme e le lisebelisoa tsa bohlokoa liindastering tse ngata, tse fanang ka ts'ebetso e ke keng ea lekanngoa ea ho cheka ka lisebelisoa tse thata. Ho tloha ho tsa kaho le tsa meepo ho isa lits'ebetsong tse khethehileng tsa tlhahiso ea semiconductor, lisebelisoa tsena tse tsoetseng pele tsa ho itšeha li tsoela pele ho fetoha ka boqapi bo tsoelang pele ba lisebelisoa, moralo le lits'ebetso tsa tlhahiso.

Bokamoso ba thekenoloji ea "diamane core bit" e ts'episa ts'ebetso e ntle le ho feta, ho nepahala, le ho feto-fetoha ha maemo ha bahlahisi ba kenyelletsa lintlha tse tsoang ho mahlale a thepa, mahlale a dijithale le boenjiniere bo tsoetseng pele. Nts'etsopele e tsoelang pele ea likotoana tse ikhethileng bakeng sa lits'ebetso tse ikhethileng, hammoho le ntlafatso ea boleng ba daemane le libopeho tsa matrix, li tla eketsa bokhoni ba lisebelisoa tsena tse ikhethang.

Ha nts'etsopele ea lits'ebetso tsa lefats'e e ntse e tsoela pele le lipatlisiso tsa lisebelisoa li kena maemong a thata, bohlokoa ba theknoloji ea "diamane core bit" bo tla eketseha. Litsebi ho pholletsa le liindasteri li ka lebella ho bona tsoelo-pele e tsoelang pele e ntlafatsang ts'ebetso ea ho cheka, ho fokotsa litšenyehelo tsa ts'ebetso, le ho nolofalletsa lisebelisoa tse ncha tseo hajoale li fetang bokhoni ba rona ba tekheniki.

Ebang ke ho theha menyetla e nepahetseng ka konkreite e matlafalitsoeng, ho fumana lisampole tsa mantlha botebong ba lefatše, kapa ho etsa hore ho be le tsoelo-pele ea taolo ea mocheso oa elektroniki, lisebelisoa tsa mantlha tsa taemane li tla tsoela pele ho bapala karolo ea bohlokoa ho bopeng tikoloho ea rona e hahiloeng le ho holisa kutloisiso ea rona ea tlholeho.

Nako ea poso: Aug-31-2025