ke hobane'ng ha u hloka "diamane core bit"?

Li-core bits tsa litaemane ke lisebelisoa tse khethehileng tsa ho cheka tse etselitsoeng ho theha masoba a hloekileng, a nepahetseng ka thepa e thata joalo ka konkreite, lejoe, litene, asphalt le lirafshoa. Lisebelisoa tsena li sebelisoa haholo mererong ea kaho, merafong le ea DIY ka lebaka la ts'ebetso ea tsona e ikhethang ea ho itšeha le ho tšoarella nako e telele. Sengoliloeng sena se shebisisa lintlha tsa tekheniki, melemo, lits'ebetso, le malebela a tlhokomelo bakeng sa likotoana tsa mantlha tsa daemane.

Diamond Core Bit ke eng?

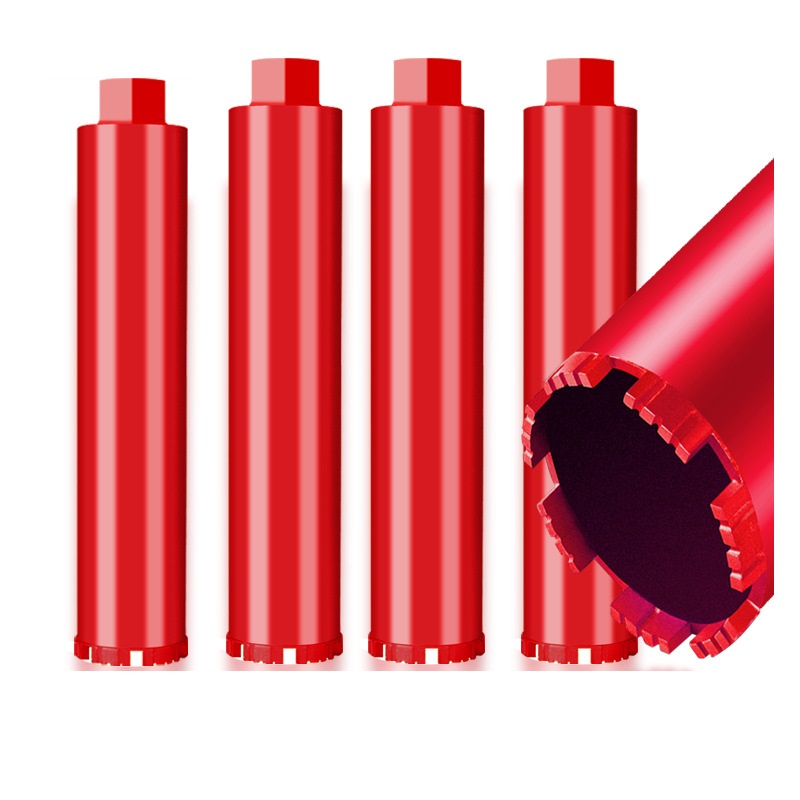

Mokotla oa daemane ke sesebelisoa sa ho cheka ka cylindrical se nang le likarolo tse kentsoeng ka daemane moeling oa sona o sehang. Litaemane, kaha ke lisebelisoa tse thata ka ho fetisisa tsa tlhaho, li nolofalletsa kotopo hore e khone ho phunyeletsa libakeng tse thata haholo habonolo. Karolo ea mantlha e tlosa thepa ka mokhoa o chitja, e siea "cylindrical" bohareng, e ka ntšoang ka mor'a ho cheka.

Lintlha le Likarolo tsa Teknoloji

- Diamond Grit le Bonding:

- Boholo ba grit ea daemane bo fapana ho latela ts'ebeliso. Li-coarser grits li sebelisetsoa ho itšeha ka mabifi, ha li-grits tse ntle li fana ka liphetho tse boreleli.

- Thepa e kopanyang (hangata e le matrix ea tšepe) e tšoara likaroloana tsa daemane sebakeng sa tsona. Li-bond tse bonolo li sebelisoa bakeng sa thepa e thata, 'me li-bond tse thata li molemo bakeng sa thepa e bonolo.

- Mefuta ea Core Bit:

- Metsi a Metsi: E etselitsoe ho sebelisoa ka metsi ho pholile hanyane le ho fokotsa lerōle. E loketse bakeng sa ho cheka ka thata ka konkreite le majoe.

- Dry Core Bits: E ka sebelisoa ntle le metsi empa ha e tšoarelle nako e telele ebile e hlahisa mocheso o mongata. E loketse lisebelisoa tse bobebe.

- Electroplated Core Bits: Hlahisa karolo e tšesaane ea litaemane bakeng sa ho cheka ka nepo empa e phela nako e khuts'oane.

- Li-Segmented Core Bits: E-ba le likheo lipakeng tsa likarolo bakeng sa ho pholisa hantle le ho tlosa litšila. E phethehile bakeng sa ho cheka ka mabifi ka thepa e thata.

- Li-Continuous Rim Core Bits: Fana ka likotoana tse boreleli, tse se nang chip, e leng se etsang hore e be tse loketseng ho cheka lithaele, likhalase le lirafshoa.

- Core Bit Diameter:

- Li-diamond core bits li fumaneha ka mefuta e mengata e fapaneng ea li-diameter, ho tloha ho tse nyane joalo ka 0.5 inches (12 mm) ho ea ho 12 inches (300 mm) bakeng sa ho cheka ho hoholo.

- Botebo ba ho Epa:

- Li-core bits tse tloaelehileng li ka cheka ho fihla botebong ba lisenthimithara tse 18 (450 mm), ha likotoana tse bolelele bo atolositsoeng li fumaneha bakeng sa masoba a tebileng.

- Ho lumellana:

- Li-diamane core bits li sebelisoa ka li-drill tsa rotary, mechini ea mantlha ea ho phunya, le liboro tse tšoaroang ka letsoho. Etsa bonnete ba hore biti e lumellana le lisebelisoa tsa hau.

Melemo ea Diamond Core Bits

- Tshebetso e phahameng ea ho itšeha:

- Li-core bits tsa litaemane li ka khaola lisebelisoa tse thata ka ho fetisisa habonolo, li fana ka masoba a hloekileng le a nepahetseng.

- Nako e telele ea ho phela:

- Ho thatafala ha litaemane ho tiisa hore likotoana tsena li tšoarella nako e telele ho feta lisebelisoa tsa khale tsa ho cheka.

- Ho feto-fetoha ha maemo:

- E loketse mefuta e mengata ea lisebelisoa, ho kenyelletsa konkreite, litene, lejoe, asphalt, ceramics le khalase.

- Katleho:

- Li-diamane core bits li cheka kapele le ka boiteko bo fokolang ha li bapisoa le likotoana tse tloaelehileng tsa ho cheka, ho boloka nako le matla.

- Hloekileng Cuts:

- Ho nepahala ha likotoana tsa daemane ho fokotsa tšenyo ea thepa le ho hlahisa masoba a boreleli, a nepahetseng.

- Lerōle le Litšila tse Fokotsoeng:

- Li-core bits, haholo-holo, li thusa ho laola lerōle le ho boloka sebaka sa mosebetsi se hloekile.

Lisebelisoa tsa Diamond Core Bits

Li-diamond core bits li sebelisoa liindastering le lits'ebetsong tse fapaneng, ho kenyelletsa:

- Kaho:

- Ho cheka masoba bakeng sa lipeipi tsa metsi, likotopo tsa motlakase, litsamaiso tsa HVAC, le liboutu tsa ankora ka konkreite le masonry.

- Meepo le Ho Koakoa:

- Ho ntša lisampole tsa mantlha bakeng sa tlhahlobo ea jeoloji le masoba a phatlohileng.

- Nchafatso le Nchafatso:

- Ho etsa menyetla ea lifensetere, mamati le tsamaiso ea moea ka har'a meaho e teng.

- Mosebetsi oa Liphaephe le Motlakase:

- Ho phunya masoba a nepahetseng a liphaephe, mehala le likhoele maboteng le fatše.

- Merero ea DIY:

- E loketse mesebetsi ea ntlafatso ea lapeng joalo ka ho kenya lishelefo, mabone kapa lisebelisoa tsa ts'ireletso.

- Mosebetsi oa Lejoe le Lithaele:

- Ho cheka masoba ka granite, 'mabole le lithaele tsa ceramic bakeng sa lisebelisoa le lisebelisoa.

Ho Khetha Bit e nepahetseng ea Diamond Core

Ho khetha karolo e nepahetseng ea daemane ho itšetlehile ka lintlha tse 'maloa:

- Thepa e Lokelang ho Ratoa: Bapisa mofuta o monyenyane le boima ba tlamahano le thepa.

- Mokhoa oa ho cheka: Etsa qeto pakeng tsa ho phunya metsi kapa ho omella ho latela litlhoko tsa morero.

- Boholo ba lesoba le botebo: Khetha bophara bo nepahetseng le bolelele bakeng sa litlhoko tsa hau tse khethehileng.

- Tšebelisano ea Thepa: Etsa bonnete ba hore karoloana e lumellana le mochini oa hau oa ho phunya kapa sesebelisoa.

Malebela a Tlhokomelo bakeng sa Diamond Core Bits

- Sebelisa Metsi bakeng sa Metsi a Metsi:

- Kamehla sebelisa metsi ho pholisa sekoahelo le ho lelefatsa bophelo ba sona ha u sebelisa li-core bits tse metsi.

- Qoba ho Futhumatsa ho Feta Ho Fetisisa:

- Sebelisa khatello e tsitsitseng 'me u qobe matla a feteletseng ho thibela ho chesa le ho senya.

- Hloekisa Kamehla:

- Tlosa lithōle le li-buildup ho tloha hanyenyane ho boloka bokhoni ba ho itšeha.

- Boloka Hantle:

- Boloka likotoana tsa mantlha sebakeng se omileng, se sireletsehileng ho thibela kutu kapa ho senyeha.

- Hlahloba Wear:

- Kamehla hlahloba likarolo tsa daemane hore li senyehe 'me u nke sebaka ha ho hlokahala.

Nako ea poso: Feb-27-2025