Likarolo tsa lehare la sakha ea daemane le likotoana tsa mantlha

melemo

1.Likotoana tsena hangata li entsoe ka lisebelisoa tse fapaneng tse kang daemane, abrasive, kapa motsoako oa bobeli. Likotoana tsa daemane li tsejoa ka bokhoni ba tsona bo phahameng ba ho itšeha le ho tšoarella nako e telele 'me li loketse ho seha lisebelisoa tse thata tse kang konkreite, masonry le majoe. Li-discs tsa abrasive hangata li sebelisetsoa ho seha lisebelisoa tse bonolo.

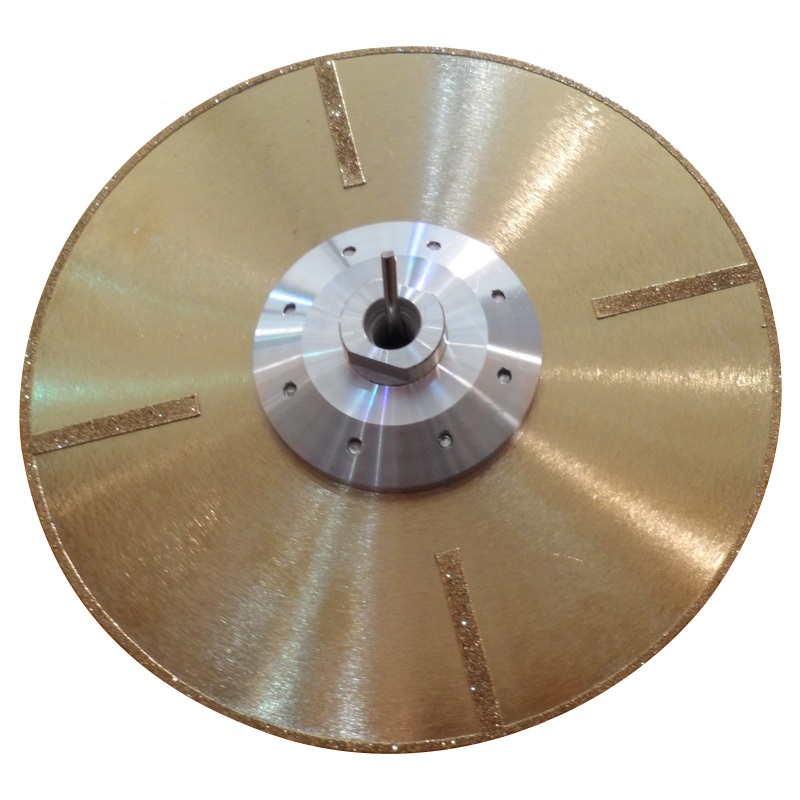

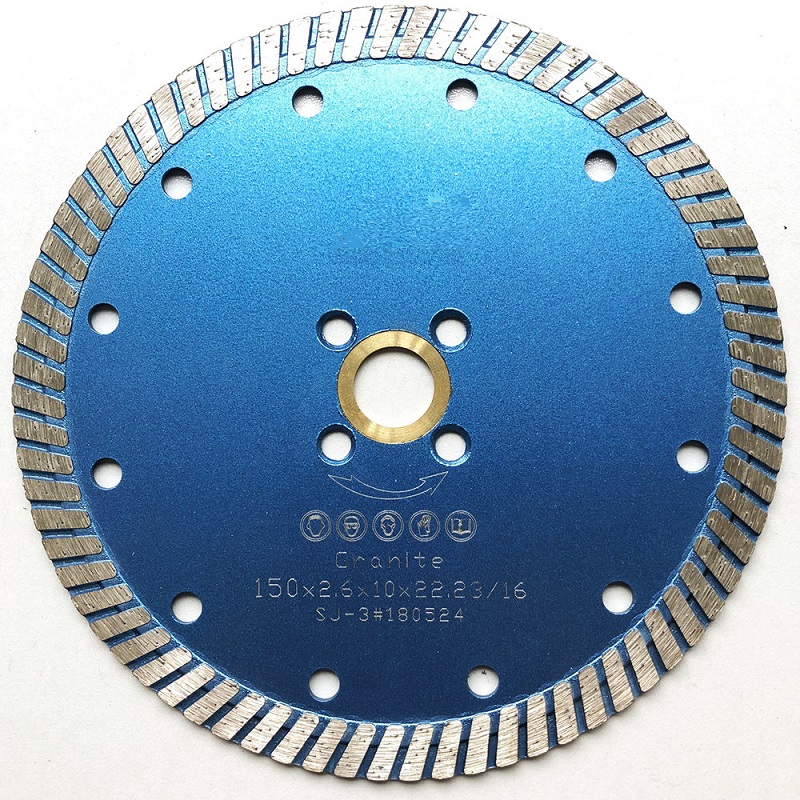

2.Sebopeho le moralo oa lehare li phetha karolo ea bohlokoa ho khetholla lebelo la ho itšeha, ho nepahala, le bokhoni ba ho senya mocheso nakong ea ho itšeha. Libopeho tse tloaelehileng li kenyelletsa turbine, wave, segmented le e tsoelang pele, e 'ngoe le e' ngoe e etselitsoe lits'ebetso le lisebelisoa tse ikhethileng.

3.Boholo ba hlooho ea sehahi, ho kenyelletsa bolelele le botenya, bo ama ka ho toba botebo ba ho itšeha le botsitso ba mokhoa oa ho itšeha. Lihlooho tse kholo li atisa ho sebelisoa bakeng sa ho itšeha ka mosebetsi o boima, ha lihlooho tse nyenyane li ka sebelisoa bakeng sa ho khaola ka mokhoa o hlakileng haholoanyane.

4.Ts'ebetso ea ho kopanya e kopanyang karolo ea lehare ho lehare la saw kapa coring bit e ama matla le botsitso ba sesebelisoa. Likarolo li ka kopanngoa ho sebelisoa mekhoa e fapaneng ea ho kopanya, ho kenyelletsa le sintering, laser welding kapa brazing, e 'ngoe le e' ngoe e fana ka melemo e itseng ho latela matla le ho hanyetsa mocheso.

5.Palo le tlhophiso ea li-bits holim'a lehare kapa li-drill tsa coring li ama bokhoni ba ho itšeha, ho senya mocheso le boreleli ba ketso ea ho itšeha. Khetha ho tsoa ho litlhophiso tse fapaneng, tse kang tse arotsoeng, tse tsoelang pele kapa turbine, ho latela litlhoko tsa hau tse ikhethileng tsa ho itšeha le lisebelisoa tse sebetsoang. \

6.Li-bits tse ling li entsoe ka likarolo tse khethehileng, tse kang tšireletso ea undercut, li-gullets bakeng sa ho tlosa litšila tse sebetsang hantle, kapa likoti tse pholileng ho thibela ho chesa haholo nakong ea ts'ebetso e telele ea ho itšeha.

7.Hlooho ea li-cutter e ka etsoa bakeng sa likopo tse khethehileng tsa ho itšeha, tse kang ho khaola konkreite, ho itšeha ha asphalt, ho khaola lithaele kapa ho phunya ka lisebelisoa tse sa tšoaneng, ho etsa bonnete ba hore ts'ebetso e nepahetseng le nako e telele bakeng sa mosebetsi o itseng.

Teko ea Sehlahisoa

MOEKETSI SEBAKA

| Lebitso la Sehlahiswa | Bophara ba lehare la sakha(mm) | Segment Dimension(mm) | Nomoro ea Karolo(li-pcs) | Sebopeho |

| Diamond Segment bakeng sa lejoe | 300 | 40×3.2×10(15,20) | 21 | B sebopeho, K sebopeho, M sebopeho, Rectangle, Sandwich sebopeho joalo-joalo |

| 350 | 40×3.2×10(15,20) | 24 | ||

| 400 | 40×3.6×10(15,20) | 28 | ||

| 450 | 40×4.0×10(15,20) | 32 | ||

| 400 | 40×3.6×10(15,20) | 28 | ||

| 450 | 40×4.0×10(15,20) | 32 | ||

| 500 | 40×4.0×10(15,20) | 36 | ||

| 550 | 40×4.6×10(15,20) | 40 | ||

| 600 | 40×4.6×10(15,20) | 42 | ||

| 650 | 40×5.0×10(15,20) | 46 | ||

| 700 | 40×5.0×10(15,20) | 50 | ||

| 750 | 40×5.0×10(15,20) | 54 | ||

| 800 | 40×5.5×10(15,20) | 57 | ||

| 850 | 40×5.5×10(15,20) | 58 | ||

| 900 | 24×7.5×13(15) | 64 | ||

| 1000 | 24×7.5×13(15) | 70 | ||

| 1200 | 24×8.0×13(15) | 80 | ||

| 1400 | 24×8.5×13(15) | 92 | ||

| 1600 | 24×9.5×13(15) | 108 | ||

| 1800 | 24x10x13(15) | 120 | ||

| 2000 | 24x11x13(15) | 128 | ||

| 2200 | 24x11x13(15) | 132 | ||

| 2500 | 24×12.5×13(15) | 140 | ||

| 2700 | 24×12.5×13(15) | 140 |

| Boholo ba karolo ea daemane bakeng sa ho cheka ha mantlha | ||||

| Bophara ba core bit (mm) | Tlhaloso | Boholo ba karolo | Nomoro ea karolo | Welding |

| 51 | Lisebelisoa tsa ho sebetsa: tiisa konkreite Khokelo: 1 1/4″ UNC; Barele: 450mm | 22*4*10 | 5 | Khafetsa koporo tjheseletsa |

| 63 | 24*4*10 | 6 | ||

| 66 | 6 | |||

| 76 | 7 | |||

| 83 | 8 | |||

| 96 | 9 | |||

| 102 | 9 | |||

| 114 | 10 | |||

| 120 | 24*4.2*10 | 11 | ||

| 127 | 11 | |||

| 132 | 11 | |||

| 152 | 24*4.5*10 | 12 | ||

| 162 | 12 | |||

| 180 | 14 | |||

| 200 | 16 | |||

| 230 | 18 | |||

| 254 | 20 | |||

| 300 | 24*5*10 | 25 | ||