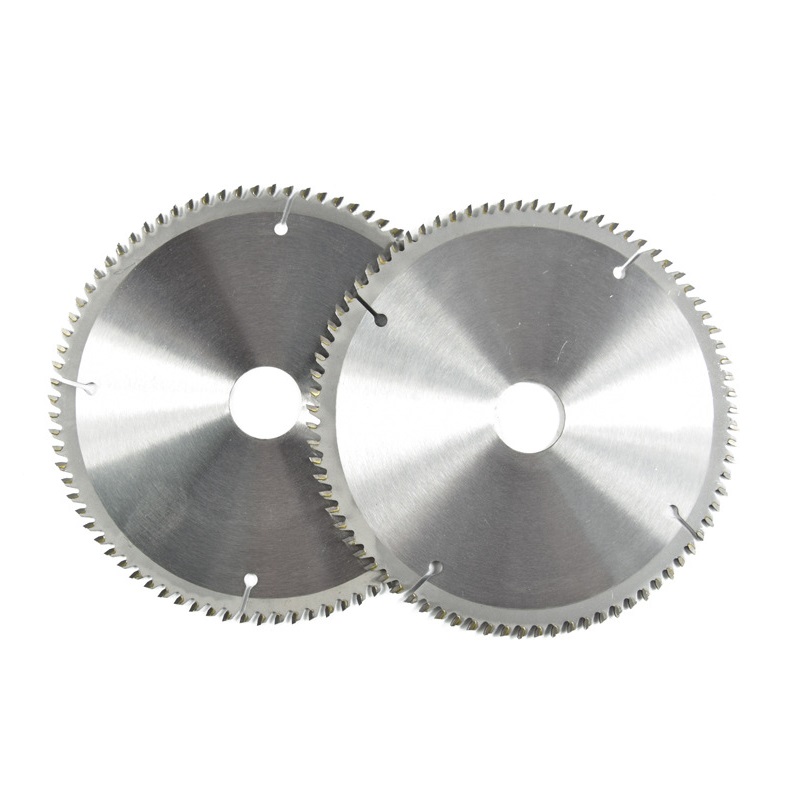

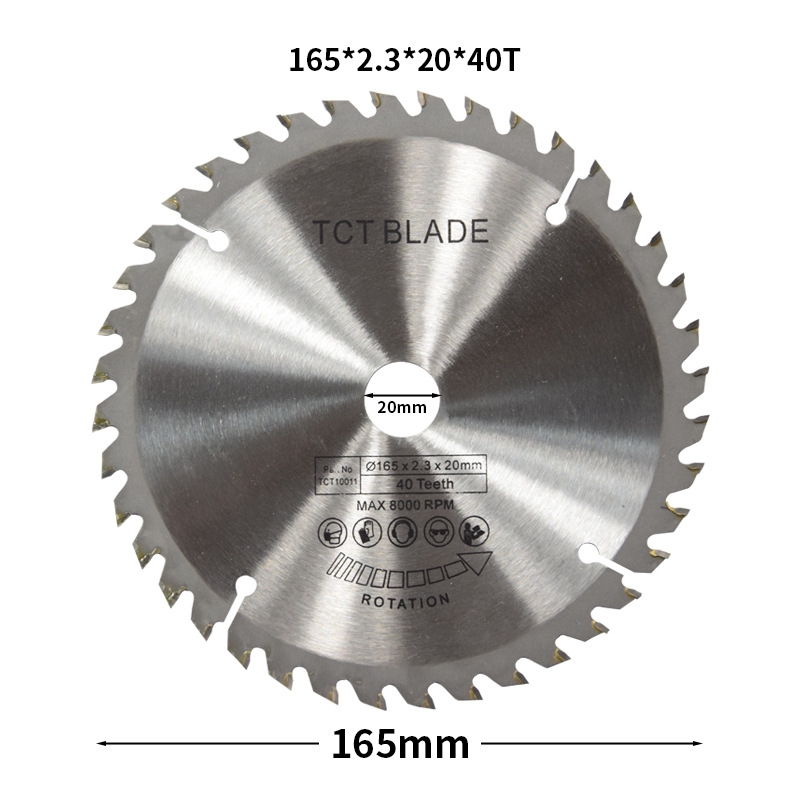

Li-disc tsa tungsten carbide tse nyane tse nang le tipped bakeng sa ho sebetsa ka lehong

Likaroloana

1. Meno a Tungsten carbide (TCT) meno: Lehare le sehang le na le meno a tungsten carbide, a thata ka ho fetisisa le a tšoarellang. Thepa ena e fana ka khanyetso e ntle ea abrasion mme e netefatsa ts'ebetso ea nako e telele ea ho itšeha, haholo ha o sebetsa ka mapolanka a thata le lisebelisoa tse ling tse thata tsa lehong.

2. Moqapi o sehiloeng ka mokhoa o mosesaane: Li-blades tsa ho itšeha hangata li nka moralo o mosesaane, o ka fokotsang litšila tsa thepa le ho fokotsa ho hanyetsa ho itšeha. Tšobotsi ena e na le molemo ka ho khetheha bakeng sa ho finyella likhahla tse boreleli le tse sebetsang hantle mererong e menyenyane ea mapolanka.

3. Phatlalatso e Phahameng: Li-discs tsena li etselitsoe ho itšeha ka mokhoa o phahameng, ho lumella ho khaola ka mokhoa o nepahetseng, o hloekileng holim'a mefuta e sa tšoaneng ea lehong. Ho nepahala hona hoa hlokahala bakeng sa ho finyella lintlha tse ntle tsa ho betla mapolanka le meralo e rarahaneng.

4. Fokotsa Vibration: Ho khaola li-discs ho ka etsoa ho kenyelletsa likarolo tse fokotsang ho thothomela nakong ea ho itšeha, e leng se etsang hore ho be le ts'ebetso e bonolo le ho ntlafatsa ho nepahala ha ho itšeha.

5. Ho senya mocheso: Ho sebetsana le mocheso o hlahisoang nakong ea ho itšeha, lehare la ho itšeha le ka 'na la e-ba le likarolo tsa ho senya mocheso, tse kang li-slots tsa ho atolosa kapa liqapi tse khethehileng tsa slot. Likarolo tsena li thusa ho laola ho bokellana ha mocheso le ho thibela ho chesa haholo nakong ea ts'ebetso e telele ea ho itšeha.

6. Ho lumellana: Lehare la ho itšeha le etselitsoe hore le lumellane le mefuta e mengata ea lisebelisoa tsa mapolanka le mechine, e lumellang hore e sebelisoe lits'ebetsong tse fapaneng tsa mapolanka.

MOKHABANE

BONTŠA SEHLAHISO