Solid Carbide Machine Reamer e nang le Spiral Flute

Melemo

1. Ho Feta ho Feta ho Thata le ho Rua Resistance: Solid carbide ke thepa e thata ka ho fetisisa le e tšoarellang e ka mamellang lebelo le phahameng la ho itšeha le ho boloka bohale ba eona ka nako e telele. Ho thatafala hona le ho se mamelle ho etsa hore mochini o tiileng oa carbide o be o loketseng ho sebelisoa lits'ebetsong le lisebelisoa tse boima.

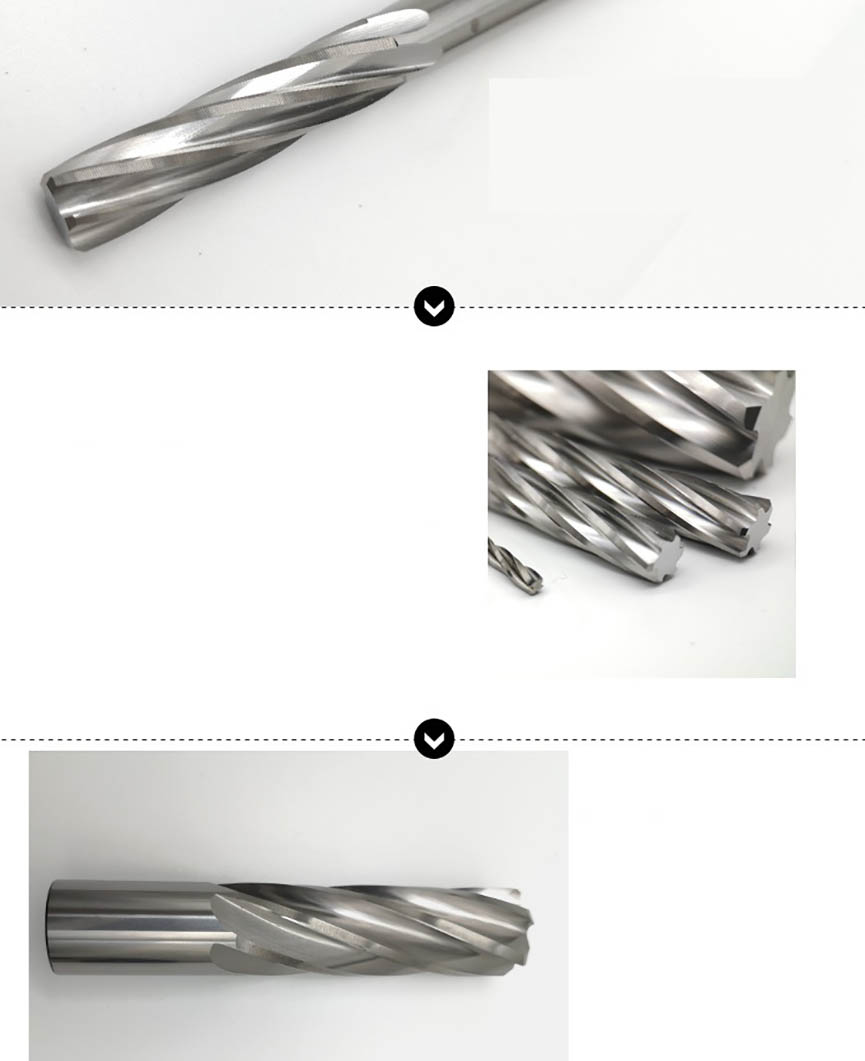

2. Phallo e Ntle ea Chip: Moralo oa spiral flute oa li-reamers tse tiileng tsa mochini oa carbide o lumella ho ntša li-chip ka katleho nakong ea ts'ebetso ea ho tsosolosa. Likoluoa tse pota-potileng li thusa ho thibela chip clogging kapa ho jamming, ho ntlafatsa ts'ebetso le tlhahiso ea sehlaseli.

3. Mabelo a Eketsehileng a ho Seha: Ka lebaka la boima ba bona bo phahameng, li-reamers tsa mochine o tiileng oa carbide li ka sebelisoa ka lebelo le phahameng la ho itšeha ho feta lisebelisoa tse ling tsa reamer. Sena se lumella ts'ebetso ea ho tsosolosa ka potlako le e sebetsang haholoanyane, ho fokotsa nako ea mochine le ho eketsa tlhahiso.

4. Qetello ea Bokaho bo Matla: Mechini e tiileng ea carbide reamers e nang le spiral flutes e hlahisa sebaka se boreleli holim'a lesoba le entsoeng ka mochine. Sebopeho sa spiral flute se thusa ho fokotsa moqoqo le ho thothomela nakong ea ts'ebetso ea ho itšeha, e hlahisang boleng bo ntlafetseng ba lesoba le ho nepahala.

5. Bophelo bo Bolelele ba Tool: Lisebelisoa tse tiileng tsa mochine oa carbide li na le nako e telele ea lisebelisoa ha li bapisoa le lisebelisoa tse ling tsa ho tsosolosa. Ho hanyetsa ha bona ho phahameng le ho tiea ha bona ho ba lumella ho mamella maemo a boima ao ba kopanang le 'ona nakong ea ho tsosolosa, ho fokotsa makhetlo a mangata a liphetoho tsa lisebelisoa le nako ea ho theoha e amanang le eona.

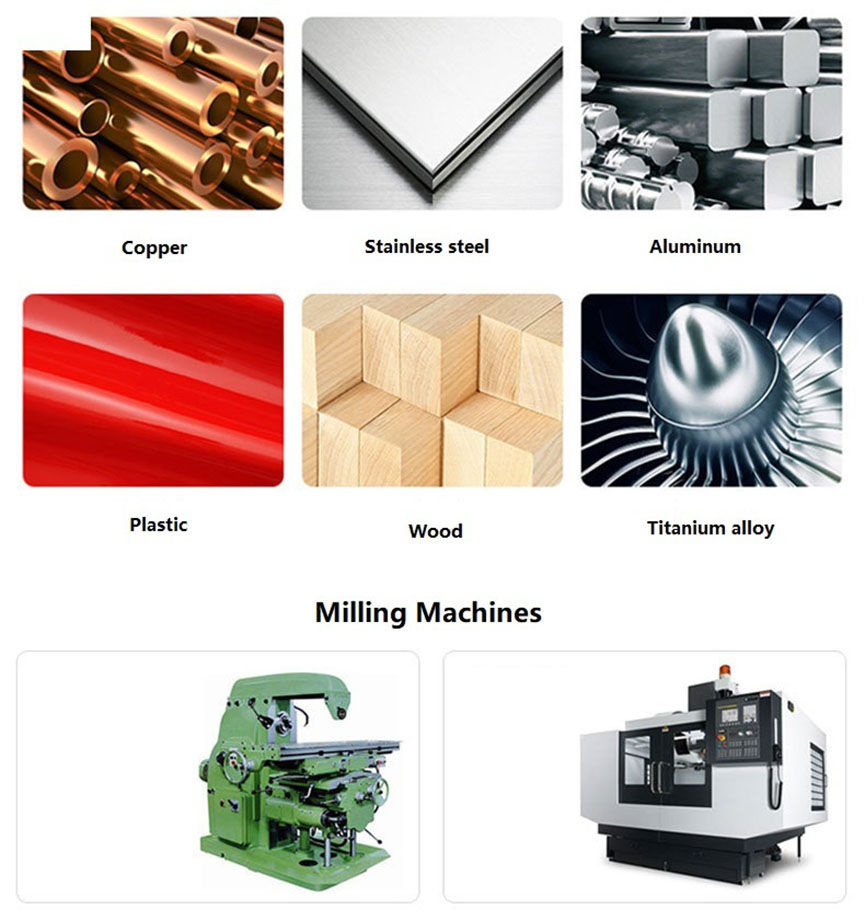

6. Ho feto-fetoha ha maemo: Mechini e tsitsitseng ea carbide e nang le flute ea spiral e ka sebelisoa mefuteng e mengata ea thepa, ho akarelletsa le litšepe, litšepe tse sa hloekang, tšepe e entsoeng ka tšepe le litšepe tse se nang ferrous. Li khona ho sebetsana le likheo tse sitisoeng le ts'ebetso e tsoelang pele ea ho khutlisetsa lintho ka lisebelisoa tse fapaneng tsa workpiece.

7. Keketseho ea botsitso ba Reamer: Moralo oa lekolilo la spiral oa li-reamer tsena o thusa ho ntlafatsa botsitso nakong ea ho seha. Sena se fokotsa ho kheloha, se thibela moqoqo, 'me se etsa bonnete ba ho theha masoba a nepahetseng haholoanyane.

8. Ho nepahala ha Dimensional: Li-reamers tsa mochini o tiileng oa carbide li etsoa ho mamellana ka thata, ho fana ka ho nepahala ho fetisisang le ho tsitsa. Sena se etsa hore li tšoanelehe bakeng sa lits'ebetso tse hlokang li-diameter tse nepahetseng tsa lesoba le mamello e thata.

9. Tlhokomelo ea Lisebelisoa tse Fokotsoeng: Ka lebaka la ho thatafala ha bona ho ikhethang le ho hanyetsa ho roala, li-reamers tsa mochine o tiileng oa carbide li hloka ho fokotsa khafetsa le ho lokisoa ha ho bapisoa le mefuta e meng ea li-reamer. Sena se fokotsa nako le matsapa a sebelisoang ho lokisoa ha lisebelisoa 'me se lumella machining a mangata a sa sitisoeng.

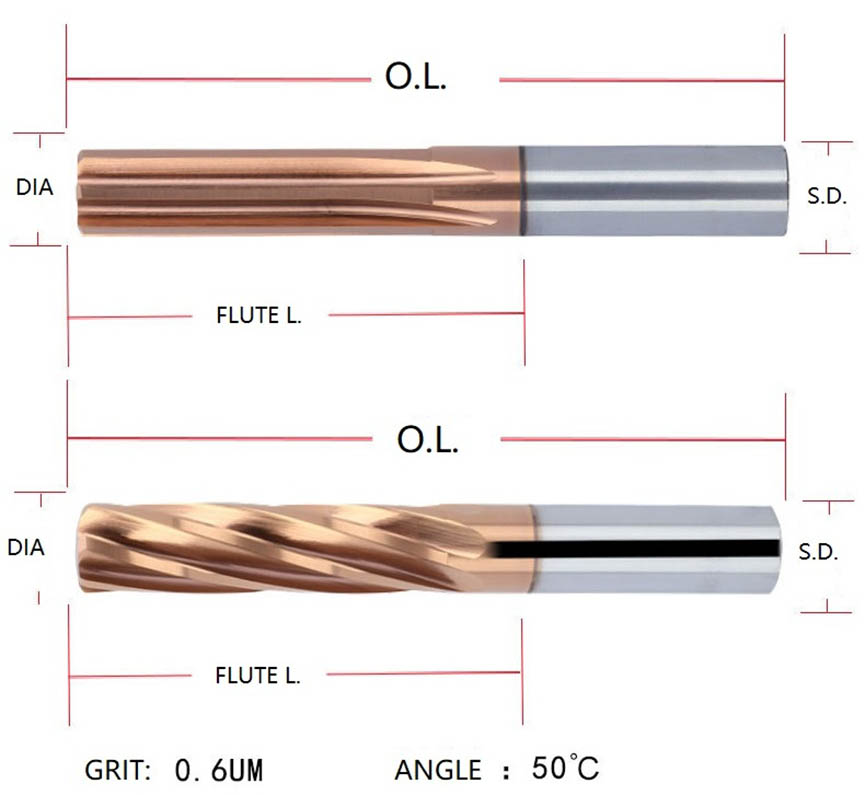

BONTŠA SEHLAHISO

| DIA | FLUTE L. | SHANK DIA | KA kakaretso L. | LIKHOPA | |

| 3 | 30 | 3D | 60L | 4F | |

| 4 | 30 | 4D | 60L | 4F | |

| 5 | 30 | 5D | 60L | 6F | |

| 6 | 30 | 6D | 60L | 6F | |

| 8 | 40 | 8D | 75L | 6F | |

| 10 | 45 | 10D | 75L | 6F | |

| 12 | 45 | 12D | 75L | 6F | |