Solid Carbide roughing End Mill

Likaroloana

1. Sekhahla se phahameng sa ho tlosa thepa: Mechini ea ho qetela ea Tungsten carbide e entsoe ka liphala tse fokolang ha li bapisoa le li-mill tse tloaelehileng. Sena se lumella chip load e kholoanyane le ketso e matla ea ho itšeha, e bakang litekanyetso tse phahameng tsa ho tlosoa ha thepa. Li loketse ho tlosa ka potlako lisebelisoa tse ngata tse sebetsang ka thata.

2. Boima bo phahameng le ho hanyetsa ho apara: Tungsten carbide e tsejoa ka thata e ikhethang le ho hanyetsa ho apara. Sena se etsa hore limilone tse thata tse entsoeng ka tungsten carbide li tšoarelle nako e telele, leha ho etsoa lisebelisoa tse thata tse kang tšepe e sa hloekang, tšepe ea alloy kapa tšepe e entsoeng ka tšepe.

3. Moralo oa meno o mahoashe: Liloala tse mahoasheng hangata li na le meno a maholo le a arohaneng haholo ha a bapisoa le a mang. Moralo ona o thusa ho fihlela phallo e sebetsang ea chip le ho thibela ho koaloa ha chip, ho netefatsa ts'ebetso e bonolo ea ho itšeha.

4. Li-Chip breakers: Li-mill tse ling tsa tungsten carbide li ka 'na tsa e-ba le li-chip breaker kapa li-splitter tsa chip metseng ea ho itšeha. Likarolo tsena li thusa ho pshatla li-chips tse telele hore li be likotoana tse nyane, tse laolehang haholoanyane, ho khothaletsa phallo e ntle ea li-chip le ho fokotsa kotsi ea tšenyo ea lisebelisoa.

5. Ho hanyetsa mocheso o phahameng: Ho hanyetsa mocheso o phahameng oa tungsten carbide ho lumella lisebelisoa tsa ho qetela tse thata ho mamella mocheso o hlahisoang nakong ea ho tlosoa ha thepa e boima. Ho hanyetsa mocheso ona ho thusa ho thibela ho senyeha ha sesebelisoa kapa ho hlōleha ha lisebelisoa pele ho nako, ho etsa bonnete ba hore lisebelisoa li phela nako e telele.

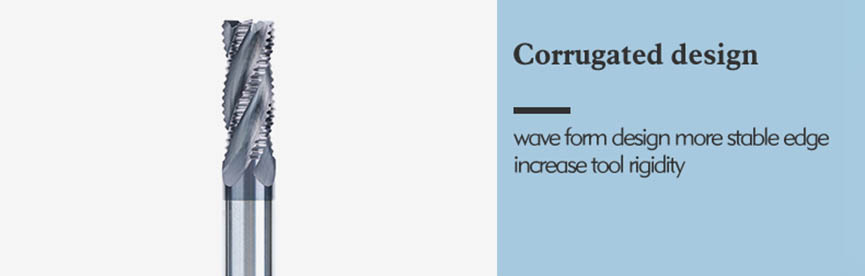

6. Moetso o feto-fetohang oa helix kapa oa ho feto-fetoha oa sekontiri: Maloala a mang a makukuno a na le sebopeho se feto-fetohang sa helix kapa sebopeho se feto-fetohang sa molumo ho liphala tsa tsona. Tšobotsi ena e thusa ho fokotsa moqoqo le ho thothomela nakong ea ho itšeha, ho fella ka ho ntlafatsoa ha holimo le ho eketsa botsitso ba lisebelisoa.

7. Likhetho tsa ho roala: Lisebelisoa tsa ho qetela tse thata li ka koaheloa ka liaparo tse sa tšoaneng, tse kang TiAlN, TiCN, kapa AlTiN. Liaparo tsena li ntlafatsa ts'ebetso ea sesebelisoa ka ho fokotsa likhohlano, ho eketsa phallo ea chip, le ho ntlafatsa ho hanyetsa ho apara. Khetho e nepahetseng ea ho roala e itšetlehile ka kopo e khethehileng le thepa ea workpiece.

8. Kaho e matla: Mehaho ea Tungsten carbide roughing end mill e hahiloe ka moaho o tiileng le o tšoarellang ho mamella litlhoko tsa ts'ebetso e thata. Li etselitsoe ho sebetsana le matla a phahameng a ho itšeha le ho fana ka botsitso nakong ea ho tlosoa ha thepa e boima.

9. Likhetho tsa Shank: Li-mill tsa Tungsten carbide roughing end li fumaneha ka likhetho tse fapaneng tsa shank, ho kenyelletsa le shank tse otlolohileng, lishanka tsa Weldon, kapa Morse taper shanks. Khetho ea shank e itšetlehile ka sesebelisoa sa mochine le litlhoko tse khethehileng tsa ho seta mochine.

10. Li-geometries tsa lisebelisoa: Li-mill tsa ho qetela tse thata li ka ba le li-geometri tse khethehileng tsa ho ntlafatsa ts'ebetso ea ho itšeha. Lijeometri tsena li ka kenyelletsa bophara ba mantlha, radii e matlafalitsoeng ea sekhutlo, kapa litokisetso tse khethehileng tsa ho ntlafatsa matla a sesebelisoa nakong ea ts'ebetso e thata.

Pontšo ea lintlha

MOKHABANE