Solid Carbide Square End Mills bakeng sa machining ka kakaretso

Likaroloana

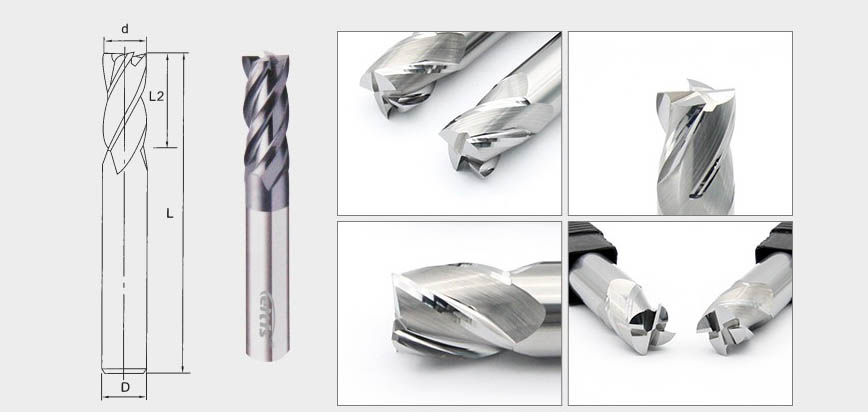

1. Boitsebiso: Li-mill tsa lisekoere tse tiileng tsa carbide li entsoe ka karolo e le 'ngoe ea thepa ea carbide, e tiisang ho tšoarella ho phahameng le ho hanyetsa ho senya le ho senya.

2. Ho thatafala: Carbide e tsejoa ka ho thatafala ha eona ho ikhethang. Li-mill tse tiileng tsa carbide square end li ka mamella lebelo le phahameng la ho itšeha le ho boloka bohale ba tsona ka nako e telele ha li bapisoa le lisebelisoa tse ling.

3. Ho nepahala: Limilili tse tiileng tsa lisekoere tsa carbide li entsoe ka ho nepahala kelellong. Li khona ho hlahisa likhahla tse nepahetseng le tse hloekileng, tse hlahisang lisebelisoa tse nepahetseng le tsa boleng bo phahameng.

4. Mefuta-futa: Litšilo tsena tsa ho qetela li ka sebelisoa mefuteng e sa tšoaneng, ho kopanyelletsa le litšepe tse nang le ferrous le tse se nang ferrous, lipolasetiki le metsoako. Ho feto-fetoha hona ho etsa hore li tšoanelehe bakeng sa mefuta e mengata ea lisebelisoa tsa machining.

5. Katleho: Li-mill tsa lisekoere tse tiileng tsa carbide li entsoe ka liphala tse ngata, tse ntlafatsang phallo ea li-chip le ho fokotsa menyetla ea ho koala. Sena se ntlafatsa ts'ebetso ea mochini le tlhahiso ea kakaretso.

6. Ho hanyetsa mocheso: Carbide e na le thepa e babatsehang ea ho hanyetsa mocheso, e lumellang li-mills tse tiileng tsa carbide ho mamella mocheso o phahameng o hlahisoang nakong ea ts'ebetso ea ho itšeha ntle le ho lahleheloa ke boima ba bona kapa bohale.

7. Nako e telele: Ka lebaka la boima ba bona bo phahameng le ho tšoarella ha tsona, li-mill tse tiileng tsa carbide square end li na le nako e telele ea bophelo ha li bapisoa le mefuta e meng ea ho qetela. Sena se fella ka ho fokotsa lisebelisoa tse ncha, ho fokotsa nako le litšenyehelo.

8. Boima bo phahameng: Mechini e tiileng ea carbide e na le ho tiea ho hoholo, ho bolelang hore ha ho bonolo hore e kobehe kapa e khelohe nakong ea ts'ebetso ea mochini. Ho tiea hona ho lebisa ntlafatsong ea botsitso ba ho itšeha le ho nepahala ha likarolo.

9. Likhetho tsa ho roala: Mechini e tiileng ea carbide square end e ka boela ea koaheloa ka liphahlo tse fapaneng tse kang TiN, TiCN, le TiAlN, tse ntlafatsang ts'ebetso ea tsona ka ho fokotsa likhohlano, ho eketsa bophelo ba lisebelisoa, le ho ntlafatsa ho tlosoa ha li-chip.

10. Geometry ea boemo bo holimo: Mechini e tiileng ea carbide square end e fumaneha ka mefuta e fapaneng ea li-geometri, joalo ka meralo e otlolohileng, ea helical le e fapaneng ea helix. Li-geometri tsena li fana ka litšobotsi tse fapaneng tsa ho itšeha 'me li fana ka litlhoko tse khethehileng tsa machining.

Pontšo ea lintlha

MOKHABANE

Melemo

1. Ho tšoarella nako e telele: Limilili tse tiileng tsa carbide square end li tsebahala ka ho tšoarella ha tsona ho ikhethang. Lisebelisoa tsa carbide ha li khone ho apara 'me li khona ho mamella lebelo le phahameng la ho itšeha le lisebelisoa tse senyang, tse bakang bophelo bo bolelele ba lisebelisoa.

2. High Speed Machining: Lisebelisoa tse tiileng tsa carbide square end li ka khona ho etsa ts'ebetso ea machining ka lebelo le phahameng ka lebaka la boima ba tsona le ho hanyetsa mocheso. Sena se lumella tlhahiso e eketsehileng le linako tse khutšoane tsa mochini.

3. Phallo e Ntle ea Chip: Mekolilo ea li-mill tse tiileng tsa carbide square end li etselitsoe ho ntlafatsa phallo ea li-chip. Sena se thusa ho thibela chip build-up le ho etsa bonnete ba ho itšeha boreleli, ho fokotsa kotsi ea ho senyeha ha sesebelisoa kapa liphoso tsa workpiece.

4. Qetello e Ntlafetseng ea Bokahohle: Li-mill tse tiileng tsa carbide square end li hlahisa likhahla tse hloekileng le tse nepahetseng, e leng se etsang hore ho be le qetello e phahameng holim'a mosebetsi. Sena se felisa tlhokahalo ea mekhoa e eketsehileng ea ho qeta, ho boloka nako le litšenyehelo.

5. Ho feto-fetoha ha mefuta-futa: Mechini e tiileng ea carbide square end e loketse mefuta e mengata ea thepa, ho kenyeletsoa litšepe, lipolasetiki le metsoako. Ho feto-fetoha hona ho etsa hore li tšoanelehe bakeng sa liindasteri tse fapaneng, ho tloha ho tsa likoloi ho ea ho tsa sefofane.

6. Botsitso bo Ntlafetseng: Mechini e tiileng ea carbide square end e na le ho tiea ho hoholo, e leng ho fokotsang ho kheloha ha lisebelisoa le ho matlafatsa botsitso ba ho itšeha. Sena se fella ka ho nepahala ho ntlafetseng le ho fokotsa menyetla ea ho senyeha ha lisebelisoa.

7. Precision Machining: Lithako tse bohale tsa li-mill tse tiileng tsa carbide square end li lumella ho sebetsa ka mokhoa o nepahetseng le o nepahetseng. Sena ke sa bohlokoa bakeng sa lits'ebetso tse hlokang mamello e tiileng le lintlha tse rarahaneng.

8. Ho hanyetsa Mocheso: Li-mill tse tiileng tsa carbide li ka mamella mocheso o phahameng o hlahisoang nakong ea ho sebetsa. Ho hanyetsa mocheso ona ho thibela sesebelisoa ho nolofatsa kapa ho lahleheloa ke thepa ea ho itšeha, ho netefatsa ts'ebetso e tsitsitseng.

9. Liphetoho tsa Lisebelisoa tse Fokotsoeng: Li-mill tsa lisekoere tse tiileng tsa carbide li na le nako e telele ea lisebelisoa ha li bapisoa le lisebelisoa tse ling, ho fokotsa tlhokahalo ea liphetoho tsa lisebelisoa khafetsa. Sena se lebisa katlehong e eketsehileng ea tlhahiso le ho fokotseha ha nako.

10. Tšebeliso ea Litšenyehelo: Le hoja qalong e ne e le theko e boima haholo, li-mill tse tiileng tsa carbide square end li fana ka poloko ea nako e telele ea litšenyehelo ka lebaka la bophelo bo atolositsoeng ba lisebelisoa le bokhoni ba ho sebetsa ka mokhoa o phahameng. Sena se etsa hore e be khetho e theko e tlaase bakeng sa ts'ebetso ea tlhahiso.

| Bophara ba lehare (mm) | Bolelele ba lehare (mm) | E felletseng(mm) | Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |