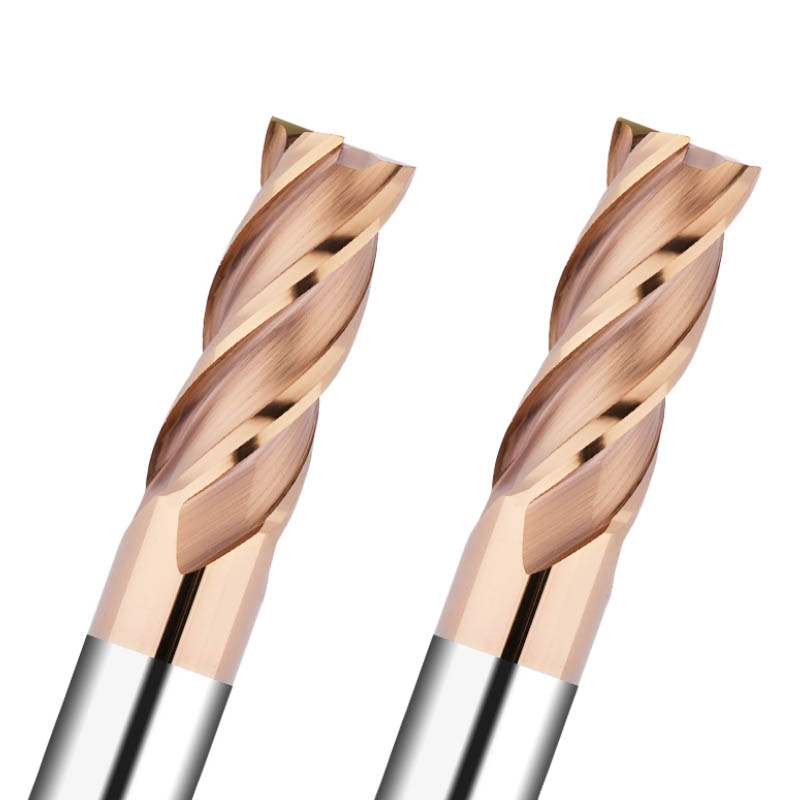

Tungsten Carbide Corner Radius End Mill

Likaroloana

1. Ts'ebetso e ntlafalitsoeng ea ho itšeha: Karolo e chitja ea leloala la ho qetela e fokotsa khatello ea maikutlo mme e fokotsa monyetla oa ho pshatla kapa ho robeha. Sena se fella ka ts'ebetso e bonolo ea ho itšeha le bophelo bo ntlafetseng ba lisebelisoa ha bo bapisoa le li-square end Mills.

2. Qetello e ntlafalitsoeng ea holim'a metsi: Sekhutlo se chitja sa leloala la ho qetela se thusa ho fokotsa matšoao a lisebelisoa le ho hlahisa sephetho se setle holim'a mochini oa mosebetsi. Sena se bohlokoa haholo ha ho etsoa likarolo tse bobebe kapa tse nepahetseng haholo.

3. Bokhoni ba ho sila ka har'a li-contour: Moralo oa radius oa sekhutlo o lumella ts'ebetso e ntle ea ho etsa contour kapa profiling. E ka latela hantle li-profiles tse kobehileng kapa tse sa tloaelehang, e fana ka mefuta e mengata e fapaneng ea libopeho tse rarahaneng tsa machining.

4. Matla a eketsehileng le botsitso: Mechini ea ho qetela ea radius ea tungsten carbide corner hangata e entsoe ka setsi se pharaletseng le likarolo tse matla tsa ho itšeha, tse matlafatsang matla le botsitso nakong ea ho itšeha. Sena se fella ka ho nepahala ho betere le ho kheloha ho fokotsehile, haholo-holo lits'ebetsong tse boima kapa tse matla tsa ho sila.

5. Ntlafatso ea ho ntša li-chip: Karolo e chitja ea leloala la ho qetela e thusa ho tsoa ka mokhoa o nepahetseng, ho thibela ho pakela chip le ho etsa hore pholiso e phalle hantle. Sena se thusa ho boloka ts'ebetso e tsitsitseng ea ho itšeha le ho fokotsa kotsi ea ho khaola chip kapa ho senyeha ha lisebelisoa.

6. Likhetho tse ngata tsa lekolilo: Li-mill tsa Tungsten carbide corner radius end li fumaneha ka likhetho tse fapaneng tsa lekolilo, joalo ka 2, 3, kapa 4 flute. Khetho ea palo ea liphala e ipapisitse le ts'ebeliso e khethehileng, lisebelisoa le litekanyetso tse lakatsehang tsa ho itšeha.

7. Likhetho tsa ho roala: Li-mill tsa ho qetela tsa li-radius tsa Tungsten carbide li ka koaheloa ka liphahlo tse fapaneng, ho akarelletsa le TiAlN, TiCN, kapa AlTiN, ho ntlafatsa ts'ebetso ea bona. Liaparo li ntlafatsa bophelo ba lisebelisoa, li fokotsa khohlano, 'me li fana ka ho hanyetsa mocheso, ho itšetlehile ka seaparo se khethehileng se sebelisitsoeng.

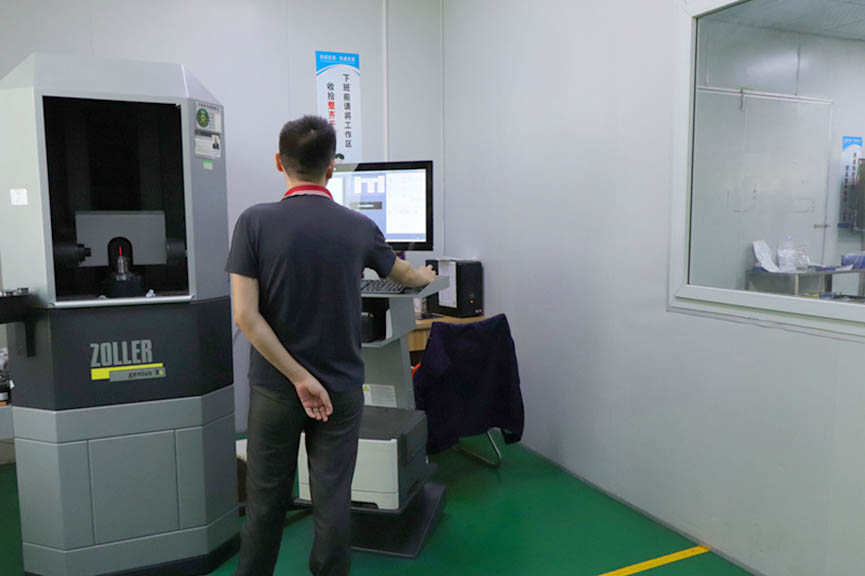

MOKHABANE