Tungsten carbide Reamer e nang le seaparo

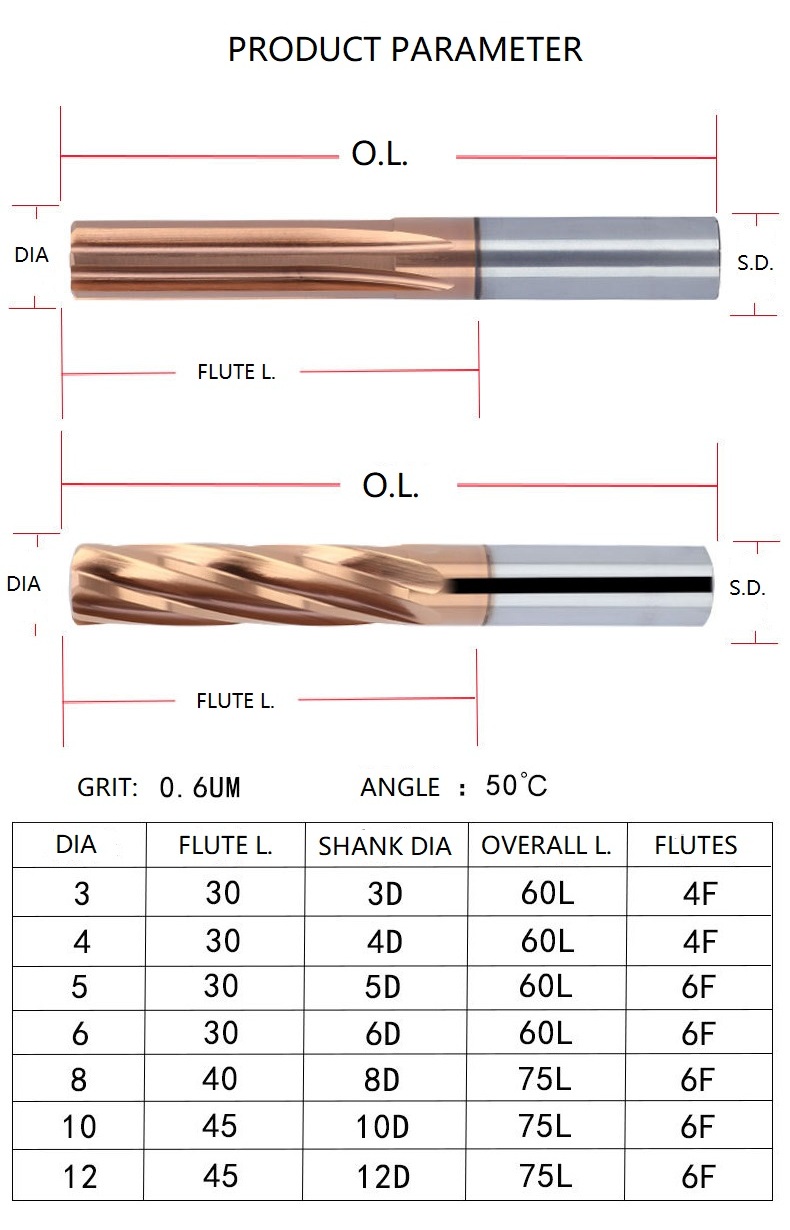

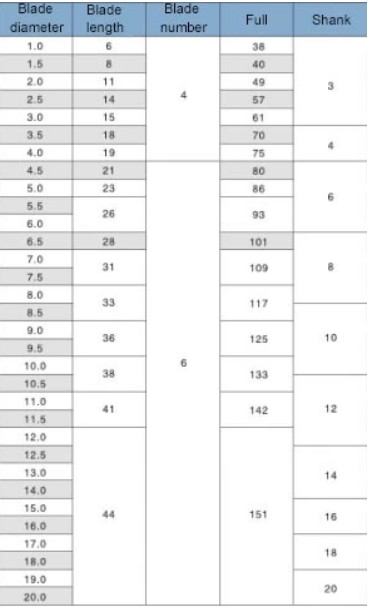

Likaroloana

Li-reamers tse koahetsoeng ka tungsten carbide li na le thepa e 'maloa e li etsang hore li sebetse haholo lits'ebetsong tsa machining. Lintlha tse ling tsa bohlokoa li kenyelletsa:

1. Ho thatafala: Tungsten carbide ke thepa e thata haholo, 'me li-reamers tse entsoeng ka eona li na le khanyetso e matla ea ho apara. Ho roala ho matlafatsa ho thatafala ha reamer le ho hanyetsa ho apara.

2. Ho hanyetsa mocheso: Li-reamers tse koahetsoeng ka tungsten carbide li ka mamella mocheso o phahameng o hlahisoang nakong ea mochine, e leng se etsang hore e be tse loketseng ho sebelisoa ts'ebetsong ea machining e potlakileng.

3. Likhetho tsa ho roala: Liaparo tsa li-reamers tsa tungsten carbide lia fapana, tse nang le liphahlo tse sebelisoang hangata tse kenyelletsang titanium nitride (TiN), titanium carbonitride (TiCN), le aluminium titanium nitride (AlTiN). Liaparo tsena li fana ka tšireletso e eketsehileng khahlanong le ho roala le ho eketsa ts'ebetso ea reamer le bophelo ba lisebelisoa.

4. Lubricity: Ho roala holim'a tungsten carbide reaamers ho ka fana ka lubricity e ntlafetseng, ho fokotsa likhohlano nakong ea ho itšeha le ho ntlafatsa ho tlosoa ha chip.

5. Ho nepahala: Li-reamers tse koahetsoeng ka tungsten carbide li khona ho etsa masoba ka mokhoa o phahameng le ho nepahala, ho etsa hore li tšoanelehe bakeng sa likopo tse nang le mamello e thata.

6. Li-Reamers tsena li ka sebelisoa ka lisebelisoa tse sa tšoaneng, ho akarelletsa le tšepe, tšepe e sa hloekang, tšepe e entsoeng ka tšepe, litšepe tse se nang ferrous le li-composite, tse etsang hore li tšoanelehe bakeng sa mefuta e sa tšoaneng ea lisebelisoa tsa machining.

7. Eketsa bophelo ba lisebelisoa: Motsoako oa tungsten carbide le ho roala o lumella hore reamer e be le nako e telele ea lisebelisoa ho feta mekhoa e tloaelehileng ea tšepe e phahameng, ho fokotsa makhetlo a mangata a liphetoho tsa lisebelisoa le ho ntlafatsa tlhahiso.

Ka kakaretso, li-reamers tsa tungsten carbide tse koahetsoeng li fana ka motsoako oa ho thatafala, ho hanyetsa mocheso le ho nepahala, e leng se etsang hore e be khetho e tummeng bakeng sa ts'ebetso e boima ea mochine.

BONTŠA SEHLAHISO