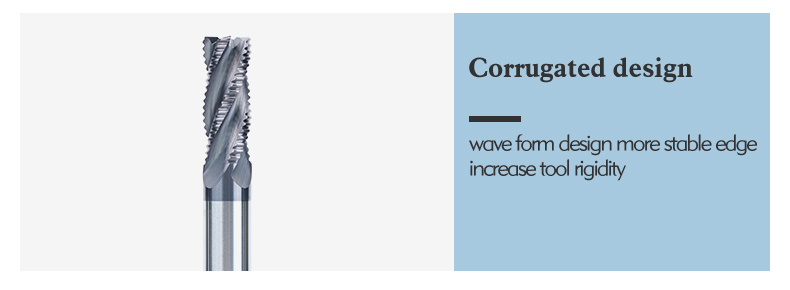

Tungsten Carbide roughing End Mill

Likaroloana

Li-mill tsa ho qetela tsa Carbide li na le likarolo tse 'maloa tse hlokomelehang:

1. Li-mill tsena tsa ho qetela li etselitsoe ho tlosa thepa ka katleho nakong ea ho phunya, ho etsa hore e tšoanelehe bakeng sa mechine e phahameng ea lebelo le ho tlosoa ha thepa e boima.

2. E entsoe ka tungsten carbide ea boleng bo holimo, limiloana tsena tsa ho qetela li fana ka boima bo phahameng le ho thatafala ho mamella mathata a ts'ebetso e thata.

3. Litšiloana tse thata li na le moralo o mahoashe oa meno o thusang ho itšeha le ho ntša li-chip, e leng se etsang hore ho be le lebelo la ho tlosa thepa ka potlako.

4. E loketse bakeng sa machining a mahlahahlaha a mefuta e sa tšoaneng ea thepa, ho akarelletsa le tšepe, tšepe e sa hloekang, tšepe e entsoeng ka tšepe le lisebelisoa tse ling tsa tšepe tse nang le ferrous le tse se nang tšepe.

5. Li-mill tsa ho qetela li etselitsoe ho mamella mocheso o phahameng o hlahisoang nakong ea ho qhoqhoa, ho fokotsa ho senyeha ha mocheso le ho netefatsa bophelo bo atolositsoeng ba lisebelisoa.

6. Li-mill tse ling tse thata li ka 'na tsa e-ba le liaparo tse khethehileng tse kang TiCN (titanium carbonitride) kapa AlTiN (aluminium titanium nitride) ho matlafatsa ho hanyetsa le ho atolosa tšebeliso ea sesebelisoa tlas'a maemo a thata a ho sebetsa. bophelo.

7. Lisebelisoa tsa ho qetela li entsoe ho fana ka botsitso le ho tiea nakong ea ho itšeha ka mabifi, ho fokotsa ho thothomela le ho netefatsa ts'ebetso e tsitsitseng.

8. Ntlafatsa moralo oa groove ea ho tlosa chip le geometry ea chip breaker, e loketseng ho tlosoa ha chip e sebetsang hantle, e thibelang ho seha bocha, le ho ntlafatsa ts'ebetso ea ts'ebetso.

BONTŠA SEHLAHISO