Tungsten Carbide Tapered End Mill

Likaroloana

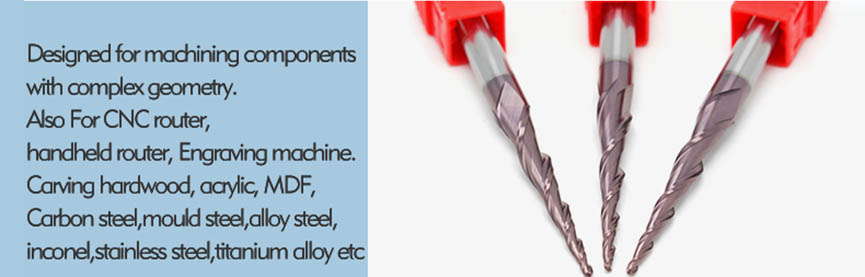

1. Bokhoni ba ho sebetsa ka mokhoa o fapaneng: Maloala a tapered a ka sebelisoa bakeng sa ts'ebetso e fapaneng ea machining, ho kenyelletsa le contouring, slotting, le ho cheka. Moralo oa taper o lumella ho tlosoa ha thepa hantle le ho itšeha ka mokhoa o nepahetseng ka litsela tse ngata.

2. Mokhoa o ntlafetseng oa ho fihlella le ho fihlella: Sebopeho se tapered sa leloala la ho qetela se fana ka phihlelo e ntlafetseng ea libaka tseo ho leng thata ho fihla ho tsona 'me se lumella hore ho be le ts'ebetso e tebileng ea ho sila. Sena se molemo haholo ha o sebetsa ka likarolo tse rarahaneng kapa ka har'a likoti.

3. Phallo e ntlafalitsoeng ea li-chip: Moralo oa lekolilo oa liloala tse tapered o thusa ho ntša li-chips ka nepo. Ka molumo oa tsona o moholo oa lekolilo le sebaka se pharaletseng, li sebetsa hantle ho tlosa li-chips sebakeng sa ho itšeha, ho fokotsa kotsi ea ho khutlisa chip le ho ntlafatsa ts'ebetso ea lisebelisoa ka kakaretso.

4. Ho eketseha ha botsitso le ho tiea: Li-mill tsa ho qetela tsa Tungsten carbide tapered li etselitsoe ho fana ka botsitso bo eketsehileng le ho tiea nakong ea ho itšeha. Sebopeho sa conical se thusa ho tsamaisa matla a ho itšeha ka mokhoa o ts'oanang, ho fokotsa ho thothomela le ho fokotsa ho kheloha, ho fella ka ho nepahala le ho qeta holimo.

5. Li-angles tse ngata tse nang le li-angles tse fumanehang: Li-mill tsa ho qetela li tla ka li-angles tse sa tšoaneng, tse kang 3 °, 5 °, 7 °, le ho feta. Khetho ea taper angle e itšetlehile ka litlhoko tse khethehileng tsa kopo, tse kang bophara bo lakatsehang ba ho itšeha le thepa e ntseng e etsoa.

6. Likhetho tsa ho roala: Lisebelisoa tsa ho qetela tsa Tungsten carbide tapered li ka koaheloa ka liaparo tse sa tšoaneng, tse kang TiAlN, TiCN, kapa AlTiN, ho ntlafatsa ts'ebetso ea tsona. Liaparo li fana ka bophelo bo eketsehileng ba lisebelisoa, ho fokotsa khohlano, le ho ntlafatsa ho hanyetsa mocheso, ho itšetlehile ka seaparo se khethehileng se sebelisitsoeng.

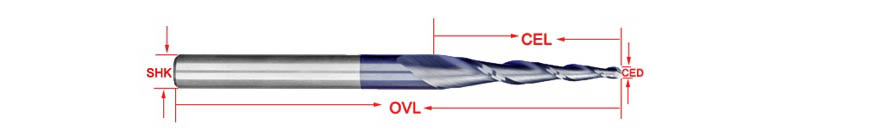

Pontšo ea lintlha

MOKHABANE

| Likolilo tse peli spiral tapered ball nose end Mills | |||||

| E sebetsang: Aluminium, polasetiki, karolo ea polasetiki, likarolo tsa koporo, motsoako oa aluminium, hlobo ea tšepe e sa hloekang, lehong | |||||

| NO | SHK | 1/2 CED(mm) | CEL | OVL | |

| 2fbn30.2515 | 3.175 | 0.25 | 15 | 38.5 | |

| 2fbn30.515 | 3.175 | 0.5 | 15 | 38.5 | |

| 2fbn30.7515 | 3.175 | 0.75 | 15 | 38.5 | |

| 2fbn31.015 | 3.175 | 1 | 15 | 38.5 | |

| 2fbn40.2515 | 4 | 0.25 | 15 | 50 | |

| 2fbn40.515 | 4 | 0.5 | 15 | 50 | |

| 2fbn40.7515 | 4 | 0.75 | 15 | 50 | |

| 2fbn41.015 | 4 | 1 | 15 | 50 | |

| 2fbn40.2520.5 | 4 | 0.25 | 20.5 | 50 | |

| 2fbn40520.5 | 4 | 0.5 | 20.5 | 50 | |

| 2fbn40.7520.5 | 4 | 0.75 | 20.5 | 50 | |

| 2fbn41.020.5 | 4 | 1 | 20.5 | 50 | |

| 2fbn60.2520.5 | 6 | 0.25 | 20.5 | 50 | |

| 2fbn60.520.5 | 6 | 0.5 | 20.5 | 50 | |

| 2fbn60.7520.5 | 6 | 0.75 | 20.5 | 50 | |

| 2fbn61.020.5 | 6 | 1 | 20.5 | 50 | |

| 2fbn602530.5 | 6 | 0.25 | 30.5 | 75 | |

| 2fbn60.530.5 | 6 | 0.5 | 30.5 | 75 | |

| 2fbn60.7530.5 | 6 | 0.75 | 30.5 | 75 | |

| 2fbn61.030.5 | 6 | 1 | 30.5 | 75 | |

| 2fbn61.530.5 | 6 | 1.5 | 30.5 | 75 | |

| 2fbn62.030.5 | 6 | 2 | 30.5 | 75 | |

| 2fbn80.547 | 8 | 0.5 | 47 | 85 | |

| 2fbn81.047 | 8 | 1 | 47 | 85 | |

| 2fbn81.547 | 8 | 1.5 | 47 | 85 | |

| 2fbn82047 | 8 | 2 | 47 | 85 | |

| 2fbn80.560 | 8 | 0.5 | 60 | 100 | |

| 2fbn81.060 | 8 | 1 | 60 | 100 | |

| 2fbn81.560 | 8 | 1.5 | 60 | 100 | |

| 2fbn82.060 | 8 | 2 | 60 | 100 | |

| 2fbn10270 | 10 | 2 | 70 | 110 | |

| 2fbn12270 | 12 | 2 | 70 | 120 | |