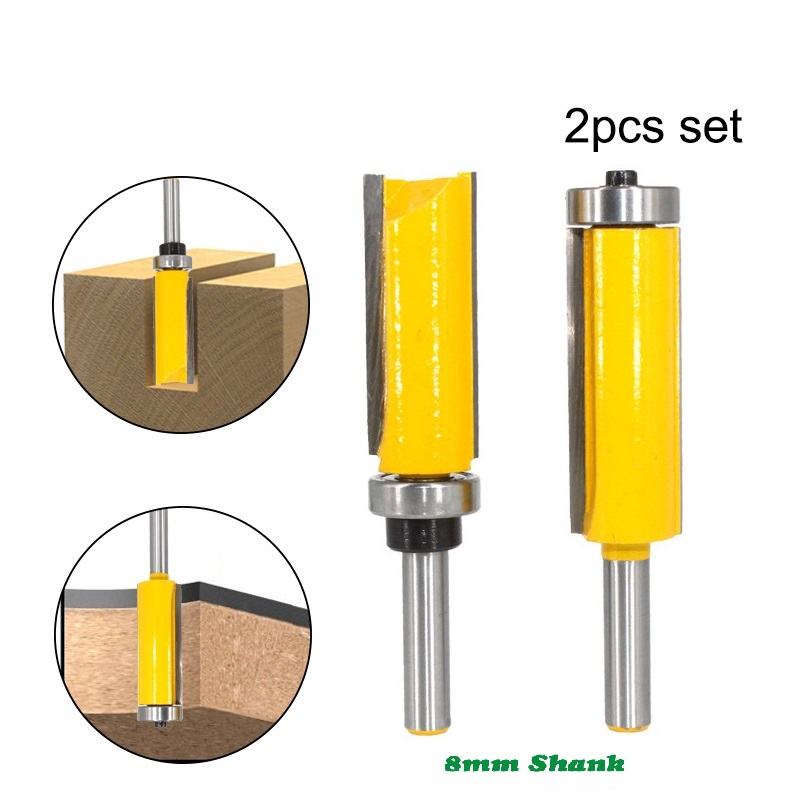

Sekhahla sa ho Tula Lehong se Nang le Li-blades tse Otlolohileng

Likaroloana

1. Moqapi oa Lehare o otlolohileng

2. Mekhahlelo e Hlakileng: Li-blades tse otlolohileng li na le mapheo a bohale, a nolofalletsang ho khaola ho nepahetseng le ho hloekisa. Bohale ba mahlakore a sehang bo lumella hore ho be le sebōpeho se nepahetseng, ho phunyeletsa kapa ho sila bokaholimo ba lehong.

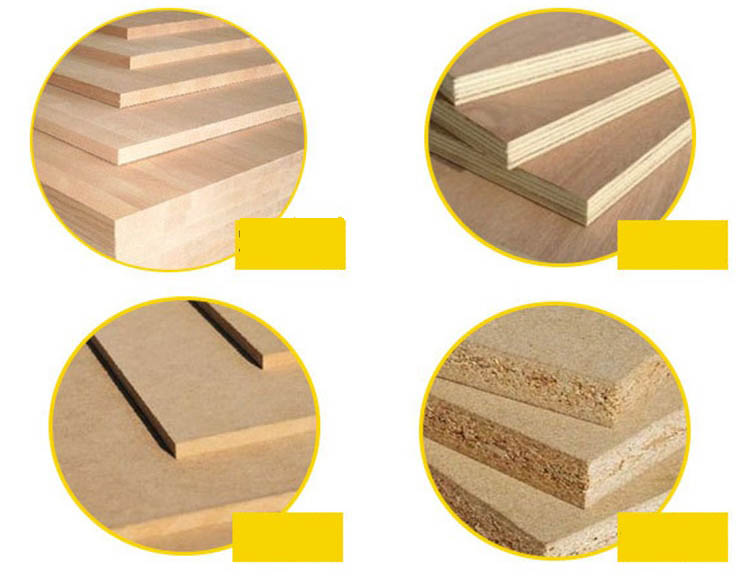

3. Mefuta e sa tšoaneng ea boholo le bophara

4. Ho lumellana: Li-cutters tsena tsa ho sila ka tloaelo li tla le boholo bo tloaelehileng ba shank, bo li nolofalletsang ho sebelisoa le mefuta e mengata ea li-routers, ho kenyelletsa le li-router tse tšoaroang ka letsoho le mechine ea CNC. Khokahano ena e tiisa ho kopanngoa ha bonolo ho li-setups tse fapaneng tsa mapolanka.

5. Phallo e Ntle ea Chip: Li-blades tse otlolohileng li etselitsoe ho ntša lithōle tsa lehong kapa li-chips ka katleho nakong ea ho itšeha. Sena se thibela ho koala le ho futhumala ha sesebelisoa, ho netefatsa ts'ebetso ea ho itšeha e boreleli le e sa sitisoeng.

6. Ho feto-fetoha ha maemo: Liseha tsa lehong tse nang le mahare a emeng li na le mefuta e mengata 'me li ka sebelisoa bakeng sa lits'ebetso tse fapaneng tsa mapolanka. Hangata li sebelisoa bakeng sa grooving, ho rema ka thōko, kapa ho etsa meralo e rarahaneng le mekhoa ea thepa ea lehong.

7. Smooth Cutting Performance: Boenjiniere bo nepahetseng le likarolo tse hlabang tsa sehahi sa leloala li kenya letsoho mosebetsing o boreleli oa ho itšeha. Sena se fella ka libaka tse hloekileng le tse phethiloeng, ho fokotsa tlhokahalo ea sanding e eketsehileng kapa boreleli.

Workshop